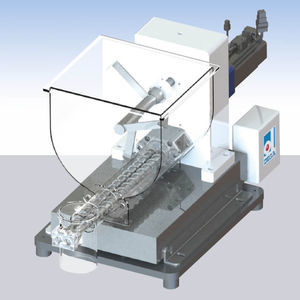

Pneumatic conveyor POWDER SPEEDfor powdersfor granulatesfor hot materials

Add to favorites

Compare this product

Characteristics

- Technology

- pneumatic

- Transported product

- for powders, for granulates

- Other characteristics

- for hot materials, vacuum, for extrusion lines, loading, feeding

Description

POWDER SPEED is the best solution for difficult material (Heavy granules, fiber glass material, wet powder) that are impossible to be feeded by vacuum. POWDER SPEED is, on Gravimetric option, useful to dose huge quantity of powder on PVC industry (extrusion) or together with ROTODOSING is possible dose and mix different materials in one station and feed into the machine or inside the mould without de-mixing or powder numb. POWDER SPEED control can manage up to 64 different receivers, and can become a Centralized Feeding System for big quantity. With Air Booster (material fluidification insdie the pipeline) POWDER SPEED can reach 100mt between the loading point and the receiver, without middle station or spare pump. Low speed used in this kind of feeding increase the pipeline life (most at all with fiber glass granules) and will avoid the angel hair or the granule’s breaking during the feeding. With 3 models: 60-80-150lt POWDER SPEED can reach 10500kg/h and distance more than 90mt.

In case the material to be feeded is hot, there’s the “H” version with >120°C proof.

Catalogs

POWDER SPEED

2 Pages

Related Searches

- Rail conveyor

- Belt conveyor

- Feeder

- Roller rail conveyor

- Food conveyor

- Stainless steel conveyor

- Automated feeder

- Screw conveyor

- Discharge conveyor

- Loading conveyor

- Inclined conveyor

- Flexible conveyor

- Aluminum conveyor

- Container rail conveyor

- Air conveyor

- Powder conveyor

- Spiral conveyor

- Granulate conveyor

- Suction conveyor

- Storage conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.