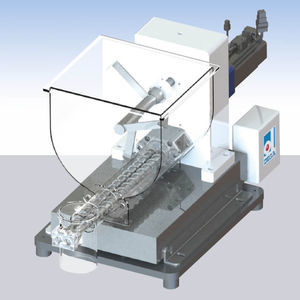

Screw conveyor ROTODOSINGloadingstoragefor powders

Add to favorites

Compare this product

Characteristics

- Technology

- screw

- Function

- loading, storage

- Transported product

- for powders, for granulates, container

- Other characteristics

- cooling

Description

In products with big volume a variation of 1-2% of the weight does not imply a perceptible difference of the cycles of plasticisation and cooling neither any difference in the quality of the product, but without any doubt this mean an extra cost to the final amount of material used. In products with medium/ small volume this difference may alter the quality of products if not duly corrected by the cycle of plasticisation. With the ROTODOSING system that guarantees the weight for each mould, these issues are resolved. The production cycle with the different weights for each mould is guaranteed by dedicated software and supported by a barcode reader that identifies each mould, speeds up the cycle and avoids any possible typing mistake made by the operator. The mechanism is very simple: The material stored in Big Bags or in specific containers is charged with a screw loader that feeds a weighed storage container placed above the moulding area; from this area an operator can get the material to all moulds thanks to a flexible pipe. The Operator with a simple bar codes reader flashes the code placed on the mould and sends the signal to the PC: this opens the valve placed under the weighed container, the system with weight loss doses the right quantity of material into the mould, in the meantime the operator flashes the code placed on the following mould and moves the loading probe into the next mould so the cycle starts.

Catalogs

Related Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Feeder

- Roller rail conveyor

- Inclined conveyor

- Stainless steel conveyor

- Food conveyor

- Automated feeder

- Screw conveyor

- Discharge conveyor

- Feeding conveyor

- Loading conveyor

- Flexible conveyor

- Aluminum conveyor

- Powder conveyor

- Container rail conveyor

- Air conveyor

- Spiral conveyor

- Granulate conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.