- Industrial machines and equipment

- Mixing and Dosing

- Resin batch blender

- Dekumed Kunststoff- und Maschinenvertrieb GmbH & C

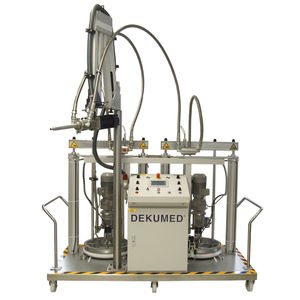

Adhesive mixer-dispenser UNIDOS 300 TX/MP 200 DOBDwith gear pumptwo-component

Add to favorites

Compare this product

Characteristics

- Product

- adhesive

- Type

- with gear pump

- Other characteristics

- two-component

Description

The Bi component meter mix and dispense machine

for thixotropic paste adhesive out of 200 litres drums

Technical Data

• Steel chassis

• Switch cabinet for electronic and pneumatic

• Follower plates 580 mm for 200 litres drum for A- and B-component, joint-less follower plate sealing

• Ceramic coated pumps in special design

• Special hardened gear metering pumps for high pressure application

• Three phase motors for A and B component, frequency controlled

• Pumps and drive motors directly mounted on follower plates

• Bleed plugs for both follower plates

• Bleed taps for bleeding pumps after drum change with manual pump start

• Low level control for drum A + B

• Speed monitoring for pump drives

• Electronic adjustable dispense quantity

• Available max dispense rates: 10 kg / min or 20 kg / min

• Pressure lines 250 bar

• Electronic mixing-ratio adjustment

• Mixing block with dynamic and static mixing

• Stainless steel dynamic and static mixing section

• Electronic mixing block motor, speed adjustable, 0 – 4.000 rpm

• Purge of mixing section with base component, 2 valve system single operated

• Swivel boom for mixing block, boom height 3 metres, cantilever length 4 metres

• All equipment mounted on a steel platform with lockable rollers > 150mm

• Acoustic and optical alarm after pot-life end and low level of material

Catalogs

No catalogs are available for this product.

See all of Dekumed Kunststoff- und Maschinenvertrieb GmbH & C‘s catalogsOther Dekumed Kunststoff- und Maschinenvertrieb GmbH & C products

Products

Related Searches

- Volumetric dosing unit

- Mixer-dispenser

- High-precision dispensing system

- Volumetric mixer-dispenser

- Resin mixer-dispenser

- Resin dispensing system

- High-precision mixing and metering unit

- Liquids mixing and metering unit

- Two-component dispensing system

- Two-component mixer-dispenser

- Multi-component mixing and metering unit

- Adhesive mixing and metering unit

- Dispensing system with gear pump

- Piston mixer-dispenser

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.