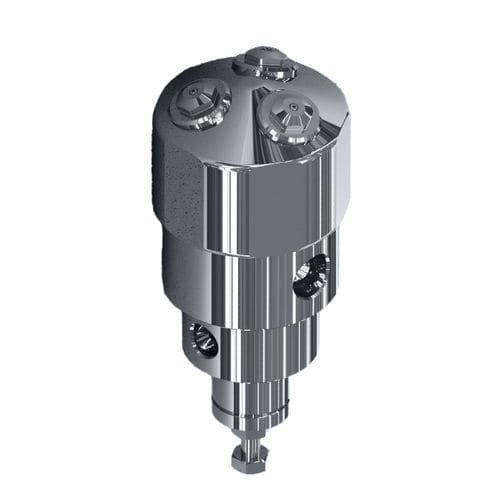

Delavan's new Variable Coating Nozzle™ offers total control for demanding Applications including those in the pharmaceutical, food and engineering industries. The VCN™ design allows the width of the spray, the atomizing air and the flow of the liquid all to be controlled independently and remotely.

Delavan has been making precision nozzles for more than 65 years and we have designed and manufactured high technology, variable width, tablet coating nozzles for a major pharmaceutical equipment manufacturer for the last 15 years.

Our latest Variable Coating Nozzle™ takes our technical leadership one step further by offering class leading atomization, superior droplet control and a host of advanced user-focused innovation

Liquid Shut Off

The flow of the liquid can be shut off automatically to avoid dripping

A special shut off sealing kit is available for use with low viscosity liquids.

Total Droplet Control

Consistency - Each VCN™ produces the same droplet spectrum throughout the run, every run.

Accuracy - Our technical expertise guarantees a closely controlled droplet spectrum

Adaptability - The VCN™ Unit is available in sizes ranging from 0.8 to 2.5mm and will cope with a wide variety of coating media. If you need help to specify a nozzle for your application please contact us.

Quality Assurance and Certification Inspection

All parts are manufactured on our world class CNC machinery and inspected at every stage of manufacture in our ISO9001 manufacturing facility.

Characterization Certificate - We are also able to to offer a full material certificate with each nozzle (nominal charge).