Interface software ZFLASHprogrammingsimulationcontrol

Add to favorites

Compare this product

Characteristics

- Function

- interface, programming, simulation, control

- Applications

- machine, for CNC machines

- Type

- real-time

Description

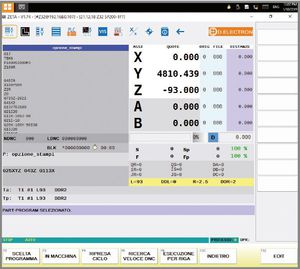

The ZFlash program is an interface that assists the operator or the programmer of a machine equipped with a Z32 CNC in the following activities:

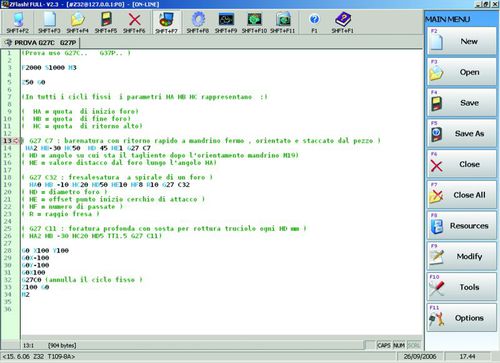

programming of macros and canned cycles and input into the program

part-program writing or editing

flat profile programming

checking for programming errors

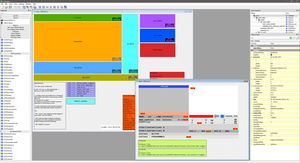

part-program simulation and control

While writing the part-program, an on-line syntax control is always active which instantly signals any typing errors. The placement of the Macro-instructions within the part-program structure is always under control and the operator can intervene at any moment to modify them or change their execution timing.

The selection of the macro-instructions to input in the part-program is intuitive and the input of the parameters is guided graphically.

The simulation of the part-program is extremely precise since it uses the same settings and the same real-time CNC software of the machine where the program will be executed; therefore it accurately generates both the geometric trajectories and the execution timings and speeds.

It is possible to handle the graphics of the geometric trajectories on screen with: zoom, rotation, change of view, diversified scale factors, etc. in order to better visualize the details.

Catalogs

Z32 Programming Depliant

8 Pages

Z32 Products

8 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.