Interface software SELCA® programmingdevelopmentcontrol

Add to favorites

Compare this product

Characteristics

- Function

- interface, programming, development, control

- Applications

- for machine tools, machining

Description

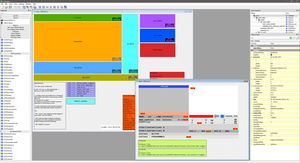

The numerical control is the interface between man and the machine tool and it truly is indispensable, especially in case of high-value pieces machining such as large molds. We are firmly convinced that our history is also our future and our products cannot ignore the experiences of the end users of numerical controls: the mold makers. We have always cared about your profession, the wealth of your experiences, the business know-how that makes your work unique, the operating habits of your workshop, all essential reference elements to which D.Electron has always looked at in the developing and the high performance usability of its CNCs.

A REAL CONTRIBUTION TO YOUR WORK

The company’s policy of growing our product along with the mold makers in order to be able to provide a real contribution with a numerical control designed and built for your specific needs, lead to the development of the "MOLDS" software function. With which the Z32 numerical control (with its functions and algorithms for managing machining and machine dynamics) allows the compatibility with the programming of part-programs written for the Selca® CNC.

SIMPLE, INTUITIVE AND FRIENDLY MACHINE TERMINAL

When the "MOLDS" option is installed it can be activated and deactivated directly by the machine operator via a softkey in the ZETA interface of the Z32, at which point it is possible to program, simulate and execute part-programs written directly in the language of the Selca® numerical control. The operator can choose whether to use the Z32 as it is usually marketed by D.Elecron or whether to activate the programming compatibility with Selca®. Basically two CNCs in one.

Catalogs

No catalogs are available for this product.

See all of D.Electron‘s catalogsRelated Searches

- Automation software solution

- Windows software solution

- Control software solution

- Real-time software solution

- Online software

- Interface software

- Simulation software

- Programming software

- Development software

- Network software solution

- Machine software

- Safety software

- PLC software

- Graphic software

- Architecture software

- HMI terminal programming software

- Milling software

- CNC machine software

- Machine tool software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.