- Packing - Handling - Logistics

- Packing and Packaging

- Automatic labeler

- DELLA TOFFOLA GROUP

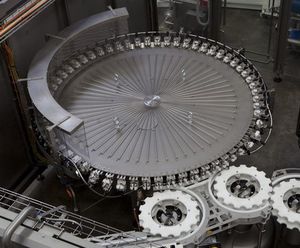

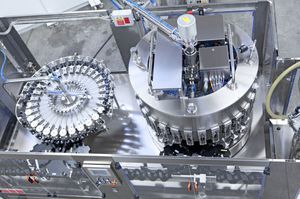

Automatic labelling machine ET 3000 AUTfor the beverage industryfor self-adhesive labelsrotary

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Applications

- for the beverage industry

- Type

- for self-adhesive labels

- Other characteristics

- rotary

- Throughput

3,000 p/h

Description

Automatic rotary labeller for attaching adhesive labels to bottles or cylindrical or square containers of wine, beverages, foodstuffs in general and cosmetics, consisting of: a body labelling station; 4 bottle-carrier plates; an inverter; an automatic speed control; a label distributor with a stepping motor; end of roll photocell; overflow photocell at inlet and outlet. The rotary labeller is delivered ready for including in the bottling line and equipped for a given type of bottle.

Made entirely of stainless steel, it is solid and strong and based on an advanced technology, achieving a high output. Designed for maximum operator safety and ease of use, it is quick to adjust and complete with safety shields.

Working direction from left to right

Output: 3000 bottles per hour

EQUIPMENT:

-station for back label

-station for DOCG round label or neckband

-turret station for transferring and attaching biadhesive DOCG neck bands or “I”-shaped labels

-plate drive motors

Catalogs

No catalogs are available for this product.

See all of DELLA TOFFOLA GROUP‘s catalogsRelated Searches

- Automatic filler

- Liquid filler

- Automatic labelling machine

- Filler for the food industry

- Bottle filler

- Food product filling machine

- Bottle labeling machine

- Volumetric filler

- Shrink wrapper

- Automatic sleeve wrapping machine

- Complete packaging line

- Container filler

- Piston filler

- Automatic capper

- Automatic complete packaging line

- Labeller for the beverage industry

- Wrap-around labelling machine

- Bottle capper

- In-line labeler

- Rotary filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.