- Packing - Handling - Logistics

- Packing and Packaging

- Automatic labeler

- DELLA TOFFOLA GROUP

Wrap-around labeller Roll-fedautomaticfor bottlesfor the beverage industry

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Product application

- for bottles

- Applications

- for the beverage industry

- Type

- hot-melt glue

- Other characteristics

- rotary, wrap-around, with servo-motor

- Throughput

Min.: 8,000 p/h

Max.: 72,000 p/h

Description

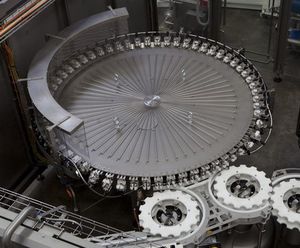

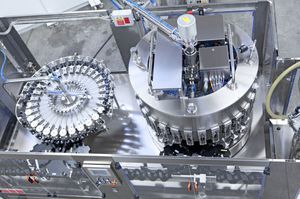

Roll-fed labellers are hot-melt rotary labeller that apply plastic or paper wrap-around labels from a reel on cylindrical or shaped containers, either empty or full.

The servomotor in the labelling unit accurately controls the stretching of the film, which is unwound, cut and transferred to the container with vacuum technology. The stainless steel glue roll distributes the glue on the edges of the labels. The roll’s design ensures a minimum consumption of glue.

Main fields of application are: beverages, mineral water, food, milk, chemical

Production speed: from 8,000 to 72,000 bph with one labelling unit.

Catalogs

Related Searches

- Automatic filler

- Liquid filler

- Automatic labelling machine

- Filler for the food industry

- Bottle filler

- Food product filling machine

- Bottle labeling machine

- Volumetric filler

- Shrink wrapper

- Automatic sleeve wrapping machine

- Complete packaging line

- Container filler

- Piston filler

- Automatic capper

- Automatic complete packaging line

- Labeller for the beverage industry

- Wrap-around labelling machine

- Bottle capper

- In-line labeler

- Rotary filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.