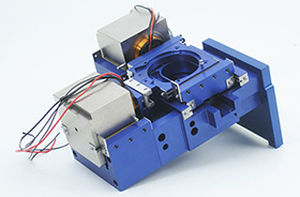

XY positioning stage linearmotorized2-axis

Add to favorites

Compare this product

Characteristics

- Orientation

- linear, XY

- Type

- motorized

- Number of axes

- 2-axis

- Other characteristics

- aluminum, custom, stainless steel

Description

A medical testing equipment manufacturer came to Del-Tron Linear Engineering for a custom motorized XY linear stage that could provide the overall accuracy, speed and reliability necessary for DNA testing. With space constraints being the major challenge, the footprint had travel, height, width and length restrictions. The custom stage also needed to be corrosion resistant. Del-Tron engineers started the design with low profile recirculating guide technology to provide the travel required in the space allotted. To minimize the stage's footprint, we also designed a combination one-piece motor flange and adjustable limit switch bracket that kept the stage well within its overall length and width requirements. This allowed the unit's travel to be adjusted when needed. All components were manufactured from stainless steel or anodized aluminum to provide corrosion resistance. The custom design of the carriage mounting brackets for both axes allowed the customer to mount their test plate to the Y plate at the required overall height.

Catalogs

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.