- Production Machines

- Forming Machine

- Electric bending machine

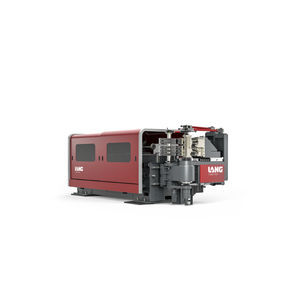

- DenglerLang Tube Tec GmbH

Electric bending machine 40CNC-EMRtubeCNC9-axis

Add to favorites

Compare this product

Characteristics

- Operation

- electric

- Product handled

- tube

- Control

- CNC

- Number of axes

- 9-axis

- Other characteristics

- mandrel, precision, draw

- Bending radius

Min.: 10 mm

(0.39 in)Max.: 160 mm

(6.3 in)

Description

The machines in the "SMALL" series offer maximum flexibility and ease of operation with fully automated tube processing. Industries that benefit from this type of machine are those requiring the highest machining accuracy in addition to high cycle times. This pioneering machine design combines high machine rigidity, the ability to produce draw bending and free-form bending processes, and the creation of multi-plane and multi-radius tools. Thanks to the complete housing and the integration of the control cabinet in the machine design, the "SMALL" series offers particularly space-saving solutions for integration in the production environment.

Applications: fuel lines, radiator and ventilation lines, automotive, aerospace, air conditioning and exhaust technology, mechanical engineering

Feature

Draw bending, free-form bending, single or multiple grooves

Minimum space requirement with optimum maintenance accessibility

Maximum tube dimension: 40 x 3.0 mm

Standard series equipment

Bending tools single or multi-stage

Central lubrication

Handheld programming device

Tube length measurement

Barrier-free access

Rittal air conditioning unit in the control cabinet

Tube and check using camera system

Colour sensor equipment for end caps

Extentsion module for ESP lines

Blow-out device

Remote machine diagnostics

Simulation software DBOF/SIM

Additional options

SVE manual control

Central lubrication

Tube length measuring system

Safety mat

Flex assembly

Software options

Remote maintenance system

Bending simulation

Tube defect test during mandrel pulling

Connection to CAD systems

Automatic conversion of binary coded 3D models

Other DenglerLang Tube Tec GmbH products

Tube bending machines

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.