- Production Machines

- Forming Machine

- Electric bending machine

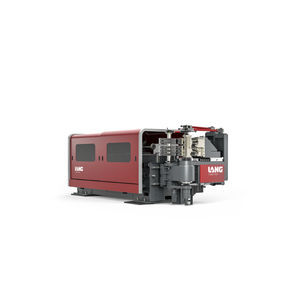

- DenglerLang Tube Tec GmbH

Electric bending machine EMR RL seriestubeCNC11-axis

Add to favorites

Compare this product

Characteristics

- Operation

- electric

- Product handled

- tube

- Control

- CNC

- Number of axes

- 11-axis, 8-axis

- Bending radius

100 mm, 160 mm

(3.94 in, 6.3 in)

Description

The "ROTATE" series offers maximum flexibility and ease of operation with fully electrical tube processing and automatic change of bend direction. This pioneering machine design combines high machine rigidity, the ability to produce draw bending and free-form bending processes, and the creation of multi-plane and multi-radius tools. In addition, the swivelling of the bending head and the tensioning and feed processes enable the shortest cycle times, and thus time savings of up to 20 percent compared to conventional processing methods.

Applications: automotive, aerospace, air conditioning, sanitation technology, hydraulics, furniture industry

Features

Time-optimized change in bending direction thanks to swivelling bend head

Reduced tooling costs – no duplicate tool set required

Maximum tube dimension: 25 x 3.0 mm

Standard series equipment

SIEMENS CNC BEND MOTION CONTROL

Automatic central lubrication

Laser scanner to protect bending area

Foot pedal for safe start

Additional options

(depending on machine)

Push-down function via the transport carriage (booster)

Free-form bending

Automatic minimum mandrel lubrication

smoothing

Programmable mandrel lifting device

Automatic clamping and counter-clamping jaw changer

Automatic multiple clamping jaw changer (max. 8-fold)

Quick-change system for bending mandrel

Wireless remote control with teach mode

Upgrade to manufacturing cell

Software options

Remote maintenance system

Bending simulation

Tube defect test during mandrel pulling

Connection to CAD systems

Automatic conversion of binary coded 3D models

Connection to measuring machine with automatic bending data correction

Password security and user code

VIDEO

Catalogs

No catalogs are available for this product.

See all of DenglerLang Tube Tec GmbH‘s catalogsOther DenglerLang Tube Tec GmbH products

Tube bending machines

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.