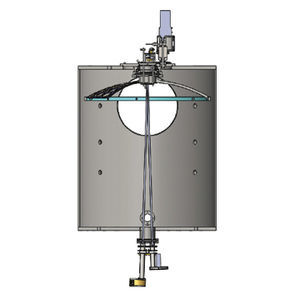

Chemical PCB etching machine Infinity FA

Add to favorites

Compare this product

Characteristics

- Type

- chemical

Description

The Infinity FA System is a cost-effective solution for etching and profiling devices with high throughput, providing rapid results at a low cost of ownership. It delivers excellent delayering uniformity and minimal damage over large areas. The fully integrated SIMS package provides the precision required to locate small defects for further analysis. By using multiple etch technologies, the etch rates of different components of a single layer can be matched, enabling uniform removal of the entire layer regardless of chemical composition.

Backed by Denton’s commitment to partnership, the Infinity FA tool delivers quality performance and high system uptime. Our global service team will provide you with a trusted preventive maintenance schedule and responsive support to ensure the best productivity and production results.

Semiconductor failure analysis

Delayering

Yield improvement

Reverse engineering

Microdisplay failure analysis

The Infinity FA System is a high-performance etching tool designed for failure analysis sample preparation, critical thin film profiling and delayering in semiconductor manufacturing. Ion beam etch (IBE), reactive ion beam etch (RIBE), and chemically assisted ion beam etch (CAIBE) are utilized to provide uniform etch rates for multi-material layers.

The system includes a robust SIMS package for analyzing thin film removal. It is ESD compliant and is fully computer controlled for high automation and repeatability. A secondary ion mass spectrometer (SIMS) enables precision endpoint control to delayer semiconductor wafers and identify defects, in order to improve process yield.

Catalogs

INFINITY FA SYSTEM

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.