- Products

- Magnetron sputtering machine

- Denton Vacuum

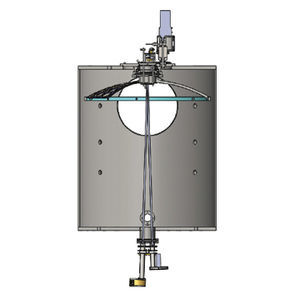

Magnetron sputtering machine Discovery 635

Add to favorites

Compare this product

Characteristics

- Options

- magnetron

Description

The production-proven Discovery platform can handle substrates up to 300mm. The cluster configuration makes it suitable for multi-layer, oxygen-sensitive applications and high throughput requirements. The platform accommodates DC, pulsed DC, and RF sputtering, which feature the single-cathode configuration for high uniformity, as well as confocal co-sputtering capability. Denton’s proprietary PEM technology enables high rate reactive sputtering of metal oxides and nitrides.

Ion assisted deposition is also available. With independent electro-pneumatic source shutters and chimney assemblies, you can prevent cross-contamination of your source material. Multiple pump configurations, including cryogenic and turbo, as well as pump placement options provide the design flexibility we need to meet your process and productivity requirements.

High-volume production

Advanced optical filters

Biocompatible coatings for medical implants

Thin film resistors & sensors

Wafer metal & dielectric films

Large area hybrid circuit fabrication

Metal contacts of compound semiconductors

Research & development

The Discovery Magnetron Sputtering system offers versatility and reliability while meeting high-volume production needs. This thin film deposition system can either accommodate a single cathode high uniformity configuration for high-volume manufacturing, or up to 4 confocal cathodes with triaxis adjustment of offset, target to substrate distance, and angle for uniform coating. Each cathode can be optimized for a different deposition method or target material.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Denton Vacuum‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.