Planetary gearbox Servox® seriescoaxial> 10 kNmflange

Add to favorites

Compare this product

Characteristics

- Type

- planetary

- Shaft orientation

- coaxial

- Torque

- > 10 kNm

- Configuration

- flange

- Number of stages

- two-stage

- Applications

- shaft, for electric motors

- Other characteristics

- large, mounted

- Gear ratio

Min.: 4 unit

Max.: 48 unit

Description

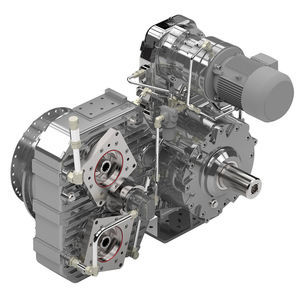

Servox® SP drive has a modified planetary gearbox and enables medium gear ratios of between 12 and 20 in coaxial arrangement. And yet the drive is only a little bit longer than a standard planetary gearbox with a similar output. These drives can be designed cost-effectively up to torque ratings of 150 kNm.

The Servox® E standard drive is equipped with a hydraulically released safety brake on the gear input shaft. The planetary gearbox in tried-and-tested Nidec DESCH quality follows in direction of the eccentric shaft. For large quantities for small to medium press forces.

A further drive version Servox® DS, offers the greatest flexibility in terms of output torque, gear ratio range and motor variation. In this case, the output torque is transmitted via planetary gearing. Depending on the geometric conditions, between two and four servo motors can produce the drive on the input side. Flexible combination of the gear ratio and the number of motors gives rise to a broad range of applications, providing customers with the drive solution best suited to their requirements.

A two-stage Servox® Z drive is available for even higher ratios and a coaxial design. Based on the standard Servox® E drive, a second planetary gear is flange-mounted on the output of the first gear stage, enabling maximum torque ratings of up to 2,000 kNm and ratios of more than i = 65. The desired output speed and the torque and speed of the available servo motors are key.

Catalogs

No catalogs are available for this product.

See all of DESCH‘s catalogsRelated Searches

- Planetary gearbox

- Coaxial gearbox

- Power transmission belt

- Flexible shaft coupling

- Gear train gearbox

- Compact gearbox

- Shafts coupling

- Transmission gearbox

- Shaft gearbox

- Multi-stage gearbox

- Single-stage gearbox

- Two-stage gearbox

- Machine gearbox

- Rubber power transmission belt

- Torque shaft coupling

- High-performance gearbox

- Spring brake

- Electric motor gearbox

- Flange gearbox

- Rigid shaft coupling

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.