- Robotics - Automation - Industrial IT

- Automation

- Modbus PID controller

- Desin Instruments

Ethernet PID controller PRC-2500Modbuspanel-mount

Add to favorites

Compare this product

Characteristics

- Input

- Ethernet, Modbus

- Mounting

- panel-mount

Description

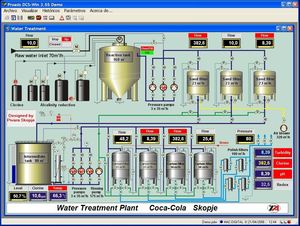

A multi-loop Control Device of 6 PID loops and Chart Recorder (paperless), to replace the classic control and mechanical record devices available in food industry , textile, etc.

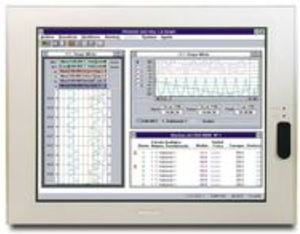

The controller is presented in a SS IP65 enclosure with a 15" touch screen facilitating the access to the control parameters (Setpoint, PID, Alarms, etc.) and other functions. All data are stored allowing up to 10 years of data storing. These devices are suitable to Control and Record of several process, even when are separated from each other, allowing daily or weekly control and recording at the same time.

CONTROL OUTPUTS FOR:

• Operating servos

• Control of servovalves

• Variable Speed drives

• Motorized valves

• Power Controllers SSR

• Electrovalves, relays, etc.

FEATURES:

• 6 (up to 32) Configurable inputs Pt100 and 4-20 mA

• 6 (up to 32) recording trends

• 6 (up to 32) PID Control loops, Autotuning and Fuzzy Logic

• 4/20 mA output or 3-15 PSI (acc./model)

• 12 (64) Alarm outputs by relay 1A, 250V

• Easy to use from the touchscreen

• Storing recording data for more than one year

• Lower cost than mechanical devices

• Saving in paper or ink maintenance costs

• Record direct download to printer

• RS-485 MODBUS or ETHERNET communication

• IP65 Stainless Steel enclosure

Catalogs

Related Searches

- Display module

- LCD module

- Digital panel meter

- Panel-mount panel meter

- Control display module

- Information display module

- Programmable display module

- Process panel meter

- Large-format display panel

- Temperature panel meter

- Current panel meter

- Programmable panel meter

- Voltage panel meter

- RS-485 converter

- RS485 display module

- Remote display module

- Industrial modem

- 4-20 mA panel meter

- RS232 modem

- Data modem

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.