- Products

- Magnetic assembly

- Dexter Magnetic Technologies

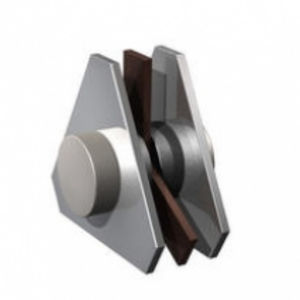

Magnetic assembly

Add to favorites

Compare this product

Description

Dipoles consist of a pair of magnets across a gap. They come in many shapes/sizes and the magnets are usually mounted on a steel frame (also called a yoke) for magnetic efficiency, magnetic shielding and/or mechanical strength. Dipoles are used when an application requires a specific magnetic field strength and uniformity over a specific volume. Pole pieces are sometimes used to enhance uniformity within the gap.

At Dexter, we have built hundreds of different types of dipoles, each optimized for a particular application. Field strengths have ranged as high as 3.0 Tesla (30,000 Gauss). Generally, higher fields are associated with small air gaps. Higher uniformity is generally associated with large air gaps.

Dipoles are used to:

Calibrate/initialize magnetic sensors

Erase computer hard disk drives

Orient thin layers of magnetic material as they are deposited as thin films

Divert or focus beams of energized particles

ESIGN HELP

When working with our engineering group, you might be asked:

What is the minimum magnetic field strength required?

How large a volume?

How large can the dipole be, does it have to fit within other devices?

Will the dipole be exposed to elevated or cryogenic temperatures?

Will the dipole be exposed to vacuum or corrosive gases/fluids?

Do you need the polarity marked?

MATERIALS

Neodymium Iron Boron and Samarium Cobalt often are used when large magnetic fields are required. Hard ferrite is used if cost is more important than large magnetic fields. Alnico is generally used if dipole is to be used in high temperature environment (>300°C).

Catalogs

No catalogs are available for this product.

See all of Dexter Magnetic Technologies‘s catalogsOther Dexter Magnetic Technologies products

Magnetic Assemblies

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.