- Hydraulics - Pneumatics

- Pump

- Plunger pump

- Dezhou United Petroleum Technology Corp.

- Products

- Catalogs

- News & Trends

- Exhibitions

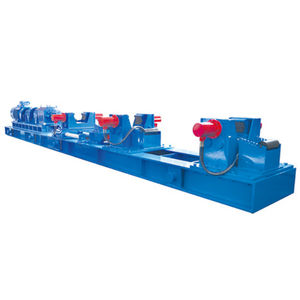

Drilling pump DTF seriesplungeroilelectric

Add to favorites

Compare this product

Characteristics

- Technology

- plunger

- Fluid

- oil

- Operation

- electric

- Mobility

- stationary

- Domain

- industrial

- Applications

- high-pressure, process, transport, for drilling

- Other characteristics

- suction, triplex, single-acting, for fluids

- Pressure

Max.: 34.3 bar

(497.479 psi)Min.: 18.5 bar

(268.32 psi)- Power

Max.: 1,275 kW

(1,733.52 hp)Min.: 224 kW

(304.56 hp)

Description

Drilling pump is also called mud pump, which transport high pressure, high specific gravity, high sand concentration drilling fluid to bottom of hole. Drilling fluid is used to cool bit, wash out bottom of hole, break rock and bring out debris. Drilling pump not only is indispensable and one of the most important processing equipments, but also is one of the three working machines of drilling rig.

DUPM mainly manufactures series mud pumps such as DTF-500, DTF-800, DTF-1000,DTF-1300 and DTF-1300, etc. Since our company realized localization of components of hydraulic end until independent R & D and production of drilling pump,we have been committed to the continuous optimization and upgrade of the drilling pump. Our DTF series products is becoming better to service oil field drilling through constant communication with customers.

Main features:

1. Products have been verified by API Q1 Quality System, comply with API Spec 7K specification, and all the parts can be traced back.

2. Strong self-suction ability. No need to use feed pump in normal case.

3. Reasonable structure. Parts has no strength redundancy. Operating steadily and reliably.

4. DUPM took the lead to realize localization of the parts of hydraulic end. After years’ experience accumulation and constant innovation, DUPM can make the manufacturing process more sophisticated and the products’ service life longer. All of these can effectively debase customers’ operation cost.

5. Valve pot, crankshaft, herringbone gear and other important parts are manufactured by high quality alloy steel. Herringbone gears adopt grinding process, which make the precision of gears higher.

Other Dezhou United Petroleum Technology Corp. products

Drilling Equipment

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.