- Packing - Handling - Logistics

- Storage

- Treatment tank

- Dezhou Weiren Water Supply Equipment Co., Ltd.

- Products

- Catalogs

- News & Trends

- Exhibitions

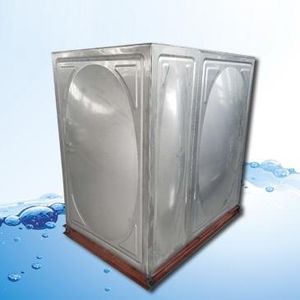

Storage tank treatmentheatingwater

Add to favorites

Compare this product

Characteristics

- Function

- storage, treatment, heating

- Product applications

- water

- Material

- stainless steel

- Type

- self-supporting, rectangular

- Applications

- for food applications, for pharmaceutical applications, for petrochemical applications, medical

Description

stainless steel sectional water tank

Product Details

Weiren company is biggest manufacture in China to produce SMC/GRP/FRP water tank , Stainless steel water tank, hot dip galvanized water tank , Enameled water tank , BDF water tank, Gush-paint water tank, etc.

Main points:

Manufacturing Standards: National Architectural Standard Design Atlas 02S101

Selection of Material: SUS304 Series, SUS316 Series or SUS444 Series

Scope of application: water supply, heating, fire control system, food, beverage, liquor making, water treatment, medicine, petroleum, etc. for various industries and civil buildings.

1. Stainless steel electrode and ER308L are used in the welding process, all of which are shielded by tungsten and argon.

2. Before welding, grooves should be made according to GB/T985-1998. The shape and size of the weld seam should conform to the requirements of JB/T794-1999, and it should be guaranteed that there is no virtual welding and slag inclusion.

3. Smooth surface, no cracks, no bubbles in the weld, uniform arrangement of lining structure and no burrs.

4. After installation of water tank, clean up and decontaminate inside and outside. After production and installation, full water test is done

Other Dezhou Weiren Water Supply Equipment Co., Ltd. products

Stainless Steel Water Tank

Related Searches

- Vessel

- Storage vessel

- Inox vessel

- Industrial vessel

- Polymer tank

- Liquid vessel

- Water vessel

- Vessel for food applications

- Pressure tank

- Vessel for pharmaceutical applications

- Water storage tank

- Transporting tank

- Water tank

- Agriculture tank

- Rectangular reservoir

- Sheet steel tank

- Process vessel

- Self-supporting tank

- Cooling vessel

- Carbon steel vessel

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.