- Industrial machines and equipment

- Mixing and Dosing

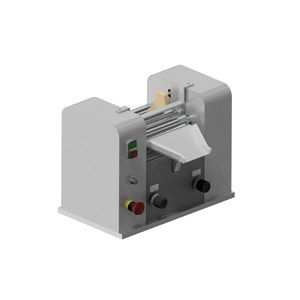

- Dosing station

- Dibir Group S.r.l.

- Products

- Catalogs

- News & Trends

- Exhibitions

Dosing station

Add to favorites

Compare this product

Description

Dibir Group produces automatic and semi-automatic machines and plants used in the cosmetic, pharmaceutical, chemical, food, other sectors for filling and capping products, in various packaging formats.

Feaures:

> Volumetric dosing system.

> Pneumatic, electric and electronic operation

(on request or depending on of the need for the product)

> Machines suitable for filling liquid, dense and semi-dense products in bottles and jars

> Heated and thermostated dosing units for hot product dosing (for example: wax, mascara, lip gloss)

> Automatic lines realized in rotary monoblocks or linear system, with different levels of speed, characteristics and performance, both alternating and continuous movement, in order to satisfy any filling and capping request for both liquid and dense products.

Depending on the requests, each machine can be made in different ways, from the ‘manual loading bottles and / or caps’ version, up to the maximum automation, thanks also to the use of robotized systems.

The automatic and semi-automatic Dibir machines can be designed, built and customized according to the specific needs of the customer.

Related Searches

- Dynamic homogenizer

- Liquid agitator

- Homogenizer for the food industry

- Solid blender

- Vertical agitator

- Agitator for the chemical industry

- In-line mixer

- Powder blender

- Agitator for the pharmaceutical industry

- Homogenizer for the cosmetics industry

- Granules blender

- Emulsifier

- Emulsifier for the food industry

- Propeller agitator

- Emulsifier for the pharmaceutical industry

- Pilot mixer

- Emulsifier for the cosmetics industry

- Turbo emulsifier

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.