Oring seal circularstainlesssteel

Add to favorites

Compare this product

Characteristics

- Type

- Oring

- Configuration

- circular

- Material

- stainless, steel, elastomeric, coated

- Application

- for pump, industrial, gearbox, for electric motors, shaft, for agricultural applications, wheel, for industrial washing, wheel

- Other characteristics

- labyrinth, acid-resistant, vulcanized

Description

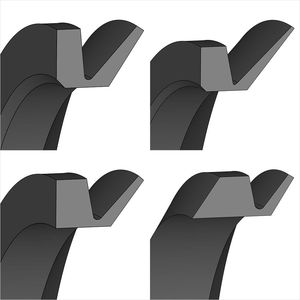

Axial seals are often used in combination with rotary shaft seals, to reliably protect against dirt, grease or fluids as modular sealing elements. Typical applications of use are electric engines, transmissions, pumps, agricultural machinery, machine tools and washing machines. The two axial seal types, VRM01 (standard) and VRM02 (with extended metal ring for use as labyrinth seal) provide a good sealing effect on the running surface. Both of them consist of a coated metal ring and a mould vulcanized elastomeric sealing element. The metal ring protects the seal against damage and acts as a flinger.

Benefits at a Glance

Reduced friction

Small installation width

VRM ring is fixed on the shaft by press fit

No additional axial stop required

Good lifetime

Very good price-performance ratio

Suitable for many industrial applications

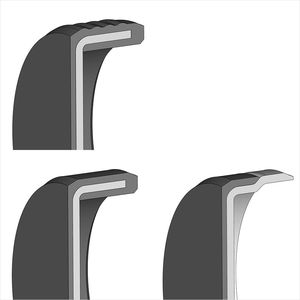

Axial seals, which are upstream elements, protect housing interiors from dirt, dust and splash water. Each axial seal consists of ,a coated metal ring and an elastomer sealing element. If desired, the metal ring is also available in stainless steel.

Depending on the requirements a standard version (VRM 01) and a special variation with an extended metal ring (VRM 02) can be offered. The seal is spread onto the metal ring but is not firmly bound to it. An axial rim collar helps to hold the ring in place.

Thanks to its centrifugal effect, the metal ring supports the sealing function and protects the elastomer sealing element from external mechanical effects. As the circumferential speed increases, the elastomer sealing element, animated by the centrifugal force, gap seal and a thrower ring

Catalogs

No catalogs are available for this product.

See all of DICHTOMATIK SAS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.