O-ring seal Lsteelrepair

Add to favorites

Compare this product

Characteristics

- Type

- O-ring

- Configuration

- L

- Material

- steel

- Application

- industrial, repair, sleeve, shaft

- Other characteristics

- radial, acid-resistant

Description

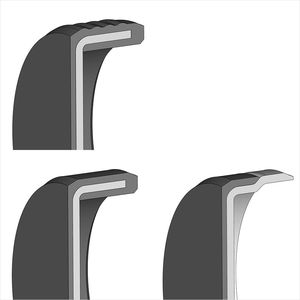

Shaft repair sleeves offer an economical solution for the repair of shafts. They are an alternative to replacing or costly reworking of the shaft. Furthermore, they are used as original equipment in machines, assemblies or facilities to avoid the complex, cost-intensive or difficult processing of shaft running surfaces. In addition to the standard types, special variants with a thicker wall are possible to order, after technical consultation. The operational application limits of use are determined by the selected radial shaft seal. The shaft repair sleeves are packed individually and are delivered with multilingual mounting instructions to ensure secure and easy installation.

Benefits at a Glance

Economical rebuilding of the shaft running surface

No costly machine downtimes

Simple and fast process

The radial shaft seal’s running surface is rebuilt permanently with full functionality

Secure fit on the shaft

Wear-resistant surface and therefore good lifetime

Retention of the original seal dimensions for simplified storage

Rust and acid-resistant steel 1.4301 (AISI 304)

Shaft repair sleeves cover the operating parameters for all catalog radial shaft seals

Very good price-performance ratio

Suitable for many industrial applications

Shaft sleeves offer an economical alternative to the replacement of elaborate post-processing of the shaft. Shaft sleeves naturally can also be used as original equipment in machines, assemblies or facilities to avoid the complex, cost-intensive or difficult processing of shaft running surfaces.

APPLICATIONS

Shaft sleeves are used to repair badly worn or degraded shaft surfaces in powertrain systems.

Catalogs

No catalogs are available for this product.

See all of DICHTOMATIK SAS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.