- Materials - Tools - Components

- Lubrication

- Single-point lubricator

- Die Lubrication Solutions Srl

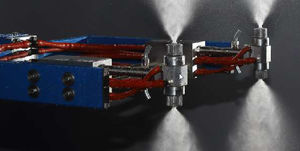

Single-point lubricator LUBSYSTEM 400 serieshydraulicautomatic

Add to favorites

Compare this product

Characteristics

- Type

- single-point

- Technology

- hydraulic

- Other characteristics

- automatic

Description

The 400 series has been designed to cover the needs of users who do not need mechanical arm movement variations but rather always use the same spraying point for similarly shaped molds.

The lubricating head is moved with a pneumatic actuator (generally rodless). A PLC makes it possible to manage lubrication time and head selection. In order to always easily find the right distance between mold and lubricating head, the height can also be adjusted manually by using the trapezoidal screw and bronze lead screw.

FEATURES:

Applied directly on the press it reduces the encumbrance area

Movement with pneumatic actuator and support guide

Ideal for a single lubrication position

ADVANTAGES:

Suitable for users who want to lubricate similarly shaped molds

Robust and reliable

Reduces the wear of parts to the minimum

Catalogs

No catalogs are available for this product.

See all of Die Lubrication Solutions Srl‘s catalogsOther Die Lubrication Solutions Srl products

HOT FORGING LUBRICATION

Related Searches

- Lubrication system

- Oil lubrication system

- Automatic lubricator

- Electric lubrication system

- Automatic lubrication system

- Single-point lubricator

- Compact lubrication system

- Multi-point lubricator

- Spray lubrication system

- Multi-point lubrication system

- Tape lubrication unit

- Programmable lubrication system

- Press lubrication system

- Mechanical lubricator

- Sheet metal lubrication unit

- Hydraulic lubricator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.