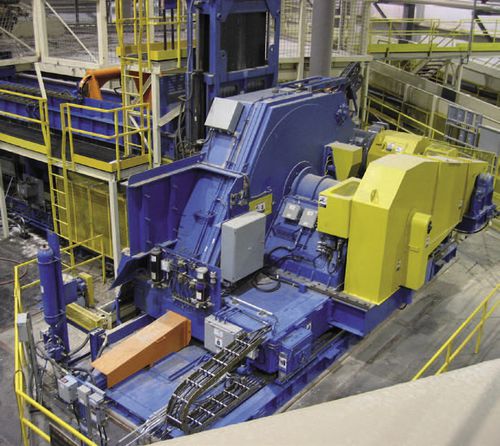

Knife ring flaker 28/81

Add to favorites

Compare this product

Description

The SmartRING Strander produces high-quality and consistent strands and is designed for easy adjustment of strand parameters. Maintenance is straightforward, and wear components are easily replaced to ensure downtime is minimized. Additionally, several features in the SmartRING platform, monitor knife installation and sub sequently identify issues, and, if necessary, act to minimize the potential of serious machine damage or catastrophic failure.

Application

Production of flakes / strands for the production of engineered wood products

OSB, OSL, and other

Customer benefits

Consistent strand quality through real-time adjustment to forward ring velocity

Knife change procedure automated through nutrunner system

Safety features minimize the potential of serious machine failure

Wear components quickly and easily replaced as required

Option to utilize disposable knives

Technical features

Real-time ring RPM monitor to adjust forward ring velocity during cutting cycle

Dimensions related to and affecting cutting properties not affected by wearing surfaces due to design of facegear components

Designed to accommodate plate or disposable knives

Automated nutrunner system ensures knives adequately clamped prior to operating

Ring design to allow complete replacement in 10-hour period

Catalogs

Product Catalog

118 Pages

Related Searches

- Grinding mill

- Production machine

- Screening unit

- Bulk material screening unit

- Rotor lump breaker

- Vibrating sieving machine

- Compact screening machine

- Continuous production machine

- Wood grinding mill

- Particle screening machine

- 2-deck screening unit

- Self-cleaning screening unit

- Pellet screening unit

- Single-deck screening unit

- Fine cutting mill

- Single making machine

- Oscillating screening machine

- Dry particulate sieving machine

- ATEX sieving machine

- Screener for the wood industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.