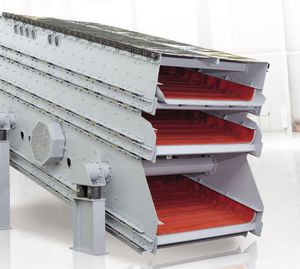

Screening unit for the wood industry ClassiCleaner+stationaryfor pelletsself-cleaning

Add to favorites

Compare this product

Characteristics

- Applications

- for the wood industry

- Type

- stationary

- Material

- for pellets

- Other characteristics

- compact, self-cleaning

Description

The ClassiCleaner+ system consists of integrated roller screening with high cleaning effectiveness and high energy efficiency. The infeed material mix is screened into different fractions, which is helpful for further processing.

Application

Panel board industry (PB, MDF)

Recycling plants

Pellet plants

Biomass and renewable energy plants

Description

The ClassiCleaner+ system consists of integrated roller screening with high cleaning effectiveness and high energy efficiency. The infeed material mix is screened into different fractions, which is helpful for further processing.

Customer benefits

Efficient impurities separation (incl. plastics)- maximum wood and biomass yield

Less wear of flaking tools, cyclones, ducting, cutting blades, etc.

Low energy consumption, low emissions

Compact design with integrated screening and cleaning

Minimum dynamic loads, light foundationsng.

Technical features

ClassiRolls with different patterns, gaps and rotation speed enable effective

screening according to screening process requirements

Sensor-based sorting

Collection of different fractions under the screen rolls

Cleaning of impurities enriched material mix

Removal of foils with suction from the roller bed

Total cleaning efficiency up to > 90% and wood yield up to > 99%

FE and non-ferrous separators and optical sorting

Capacity range 10 - 60 t/h b.d.

VIDEO

Related Searches

- Grinding mill

- Production machine

- Screening unit

- Bulk material screening unit

- Rotor lump breaker

- Vibrating sieving machine

- Compact screening machine

- Continuous production machine

- Wood grinding mill

- Particle screening machine

- 2-deck screening unit

- Self-cleaning screening unit

- Pellet screening unit

- Single-deck screening unit

- Fine cutting mill

- Single making machine

- Oscillating screening machine

- Dry particulate sieving machine

- ATEX sieving machine

- Screener for the wood industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.