Air separator 8,0 Rcyclonemetalsand

Add to favorites

Compare this product

Characteristics

- Technology

- air, cyclone

- Separated substance

- metal, sand, glass

- Other characteristics

- high-efficiency

- Flow

Max.: 26,000 m³/h

(918,181.335 ft³/h)Min.: 12,600 m³/h

(444,964.801 ft³/h)

Description

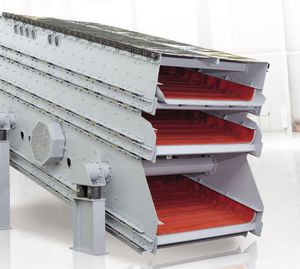

The air grader splits the incoming material into three fractions: acceptable material, coarse material (e.g., high density contaminants or wood particles of undesirable geometry such as needles, etc.) and material falling through the screen decks (mostly sand, minerals, glass, etc.). The product enters the suspension chamber (of the air grader) via a rotary valve and a central tube. Agitator arms distribute the material uniformly over the perforated plate through which air is drawn. Different grades of separation are achieved by varying the air velocity. The heavy coarse material is moved to the outside of the grader and leaves the suspension chamber via rotary valves. The accepted material is suspended in the air stream and separated from the air in high-efficiency cyclones.

Application

Particleboard industry

Separation of foreign materials such as sand, stones, metal or bark

Separation for core and surface particles

Separation of the flakes depending on the flake thickness

Customer benefits

Precise separation according to particle thickness

Excellent removal of heavy contaminants

Low maintenance costs

Safe and reliable design

Continuous and consistent separation at all operating modes

High capacities with one unit

Low exhaust volume

Technical features

Up to 85% of the air is recirculated while the remaining volume is cleaned before venting into atmosphere

High-efficiency cyclones

Explosion protection system conforming to ATEX

Air grader suspension chamber with:

Agitating device with continuous cleaning system

Quick change device for the upper screen

Conical drilled holes in upper screen deck

Catalogs

Product Catalog

118 Pages

PROjet

11 Pages

Related Searches

- Solid classifier

- Centrifugal classifier

- Gravity classifier

- Ferrous metal separator

- Air classifier

- Automatic separator

- Cyclone classifier

- High-efficiency classifier

- Vertical classifier

- Sand classifier

- Flow separator

- Glass separator

- Horizontal classifier

- Rubber classifier

- Classifier for the wood industry

- Fiber classifier

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.