Air separator SGF cycloneflowfiber

Add to favorites

Compare this product

Characteristics

- Technology

- air, cyclone, flow

- Separated substance

- fiber

- Application domain

- for the wood industry

- Other characteristics

- vertical

- Flow

17,400 m³/h, 26,100 m³/h, 30,400 m³/h, 38,800 m³/h

(614,475.201 ft³/h, 921,712.801 ft³/h, 1,073,565.868 ft³/h, 1,370,209.069 ft³/h)

Description

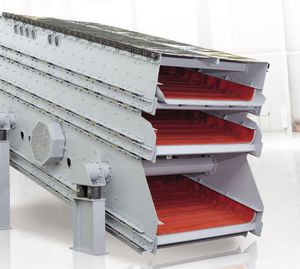

The Air Grader separates the material in the vertical air flow over two sifting stages. Heavy and coarse material is discharged via screw conveyors and downstream arranged rotary valves. The accepted material is conveyed pneumatically to a high efficiency cyclone. There, the material is separated from the air flow and discharged by an air lock.

Application

The SGF-Air Grader is used in the MDF, HDF, THDF and door skin production for separating:

Wood particles

Glue lumps

Coarse fibers

Metal rubber and other foreign material

Customer benefits

Increased product quality

Simple and reliable

Low operating costs and maintenance effort

Low exhaust volume

Reduced risk of press damage

Safe design according to high European Standards

High press performance by avoiding fiber temperature drop from dryer to forming

Technical features

No internals which could cause blockages

Design according to ATEX directives with pressure relief and/or explosion suppression

Fan impeller with high efficiency

Air grader process with usage of up to 70% recirculated air

Pressure control to enable adjustments of capacities

Fan arrangement on clean air side downstream cyclone prevents wear on fan impeller and impeller housing

Process Heating system

Catalogs

Related Searches

- Solid classifier

- Centrifugal classifier

- Gravity classifier

- Ferrous metal separator

- Air classifier

- Automatic separator

- Cyclone classifier

- High-efficiency classifier

- Vertical classifier

- Sand classifier

- Flow separator

- Glass separator

- Horizontal classifier

- Rubber classifier

- Classifier for the wood industry

- Fiber classifier

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.