Cyclone separator Z 2750/2270 RWairmetalrubber

Add to favorites

Compare this product

Characteristics

- Technology

- air, cyclone

- Separated substance

- metal, rubber, fiber

- Application domain

- for the wood industry

- Other characteristics

- automatic, horizontal

Description

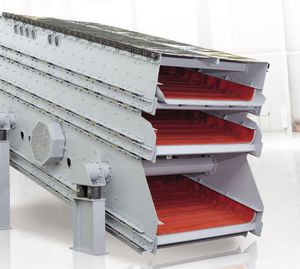

Fibers from the dryer are getting accelerated by a horizontal air stream in inlet section and spread in Zigzag section. Vortexes, caused by zigzag shaped internals, separate coarse from fine material. Coarse particles fall down to sifter bottom section and get transported out by two screw conveyors. Accept-able material gets carried upwards and out of sifter to a high efficiency cyclone above the forming sta-tion. There, the material is separated from the air flow and discharged by an air lock.

Application

Used in MDF, HDF, THDF and door skin production for separating:

Glue lumps

Coarse fibers

Latex particles

Wood particles

Metal, rubber and other foreign material

Customer benefits

Outstanding sifting performance and excellent separation accuracy

Reduced risk of press damage

Safe design according to European standards

Low exhaust volume

Proven technology for rubber wood

Fully automatic operation

High press performance by avoiding fiber temperature drop from dryer to forming

Technical features

Inlet section with blow box and coanda separation technology

Two steps of reject collection with distribution plate and vibrator

Design according to ATEX directives with pressure relief and/or explosion suppression

Z-Sifter process with usage of up to 70% recirculated air

Sifter section with proven zigzag plates

Sifter performance controlled via pressure and air flow according to capacity

Process heating system

Catalogs

No catalogs are available for this product.

See all of Dieffenbacher‘s catalogsRelated Searches

- Solid classifier

- Centrifugal classifier

- Gravity classifier

- Ferrous metal separator

- Air classifier

- Automatic separator

- Cyclone classifier

- High-efficiency classifier

- Vertical classifier

- Sand classifier

- Flow separator

- Horizontal classifier

- Glass separator

- Rubber classifier

- Classifier for the wood industry

- Fiber classifier

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.