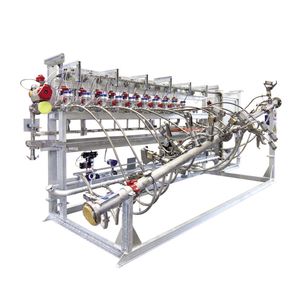

Volumetric dosing unit UBG beltfor the wood industry

Add to favorites

Compare this product

Characteristics

- Type

- volumetric, belt

- Applications

- for the wood industry

Description

Dosing bins are typically installed for both SL and CL flakes. The first task of the bins is to equalize the flake flow from the storage silos to gluing. The bins’ second and main task is to accurately dose the flakes into the blenders.

Application

Surface layer (SL) and core layer (CL) flake dosing for gluing particles

Customer benefits

Accurate dosing of flakes into the glue blenders

Accurate mass flow measuring with belt scale (deviation < 1%)

Continuously monitoring the filling level ensures accurate level control

Technical features

Dosing bin capacity for buffering between the process steps

Belt scale with discharge roller and mat height monitoring

Aligned to EVOjet P for convenient integration

Volumetric level monitoring with guard against overfilling

ATEX classification: Category 1/3 or 2/3, according to Annex 1 of 94 / 9 / EC used in zone 20

Rake rolls inside the bin for equalizing the material flow to the scale

Belt speed control to ensure a smooth material flow into blending

Sampling tube for secure extraction of material

Extinguishing device for the entire bin

Catalogs

No catalogs are available for this product.

See all of Dieffenbacher‘s catalogsRelated Searches

- Rail conveyor

- Belt conveyor

- Volumetric dosing unit

- Drag chain conveyor

- Bulk products conveyor

- Loading conveyor

- Inclined conveyor

- Gravimetric dosing unit

- Vibrating conveyor

- Conveyor for heavy-duty applications

- Conveyor for the wood industry

- Storage conveyor

- Wood conveyor

- Trough conveyor

- Plate conveyor

- Crawler conveyor

- Belt dosing unit

- Panel conveyor

- Screening conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.