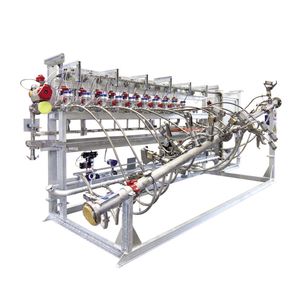

Paddle blender CB batch

Add to favorites

Compare this product

Characteristics

- Technology

- paddle

- Batch/continuous

- batch

Description

Glue blenders provide uniform glue distribution due to large chamber volume and long retention time. A constant filling level of the blender is maintained by a discharge flap to ensure an optimum gluing result. According to the filling level the power consumption of the main motor is controlled.

Application

Particleboard plants

Customer benefits

Uniform glue distribution

Separate cooling water infeed for shell and shaft

Long retention time

Open PLC-based flap control

Technical features

Available with either screw intake (CL) or paddle intake (SL)

Mixing chamber, mixing tools and discharge flap are water cooled

Electrically actuated cover opening

Mixing chamber is manufactured with wear-resistant material, highly wear-resistant coating option available

Blender retention time controlled by discharge flap adjustment

Ready for EVOjet P

Catalogs

Product Catalog

118 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.