- Products

- Gluing machine

- Dieffenbacher

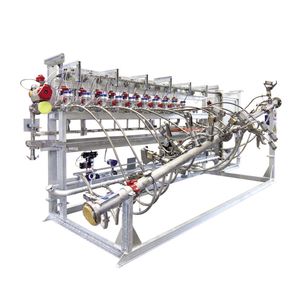

Two-roller glue spreader EVOjet P

Add to favorites

Compare this product

Characteristics

- Options

- two-roller

Description

EVOjet is the resin application system made by Dieffenbacher. EVOjet P allows high resin savings achieved by finely atomized resin distributed by two-component nozzles. These special nozzles create a homogeneous resin droplet distribution on the particles.

Application

Gluing for particleboards

Customer benefits

Up to 15% resin savings in the core layer compared to common blender technology

Standard glue pumps can be used – no additional equipment needed

Less humidity might result in a reduction of press factor

Technical features

Two fast-rotating spike rollers ensure homogeneous particle distribution

Compressed air as atomization medium

All parts in contact with resinated particles are stainless steel

Special component nozzles for low-pressure gluing

Internal cleaning units: swiveling plates and rotating scraper with wire rope

Integrated transport device to move the blending chute into maintenance position

VIDEO

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.