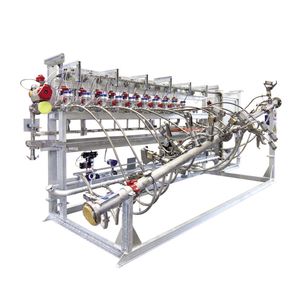

Glue dispensing machine EVOjet M 2.0

Add to favorites

Compare this product

Description

EVOjet M 2.0 is the next generation of dry resin application systems. After drying, a trap separates coarse foreign particles from the fibers to protect the spike rolls. These fast-rotating rolls dissolve the fiber stream before entering the resinator. Special nozzles atomize the glue into the finest droplets to guarantee optimum gluing of the fibers. Controlled protection air is added to prevent sticking of the freshly glued fibers. Downstream, a unique air slide elbow works in combination with recirculated fibers to prevent contact between resinated fibers and the surrounding ductwork.

The EVOjet M 2.0 is available for new production lines and as retrofit in existing plants.

Application

MDF/HDF panel industry

Wood fiber insulation industry

All kinds of resin

Customer benefits

Superior fiber/resin contact

Reduced emissions out of the dryer

Less pre-curing of the resin

Resin savings up to 25% compared to conventional blow line

Proven flow technology for minimum cleaning

Technical features

Two fast-rotating spike rollers ensure a high-quality board surface

Externally arranged nozzles atomize the resin into defined droplets size

Visual online monitoring of the process through inspection window

ATEX-approved

Easy access through inspection doors and hatches

Dissolved fiber flow is sprayed with glue

Fully automatic self-cleaning of the nozzles without interrupting the production

Protection air prevents sticking in the system for minimum cleaning effort

System capacity up to 48 t/h b.d. of fiber with a single EVOjet M 2.0

VIDEO

Catalogs

No catalogs are available for this product.

See all of Dieffenbacher‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.