- Products

- Automatic gluing machine

- Dieffenbacher

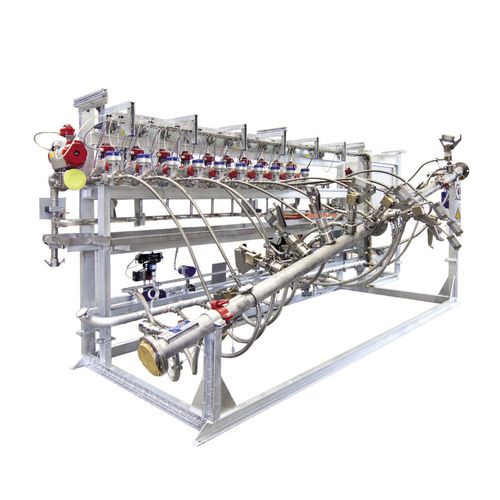

Automatic gluing machine PROjet

Add to favorites

Compare this product

Characteristics

- Options

- automatic

Description

The well-proven PROjet system applies resin and additives directly to wood fibers in the blow line. It consists of a resin injection tube with steam atomizing nozzles, a distribution unit with valves, sensors and a water booster station for cleaning.

Application

MDF/HDF panel industry

Applicable for UF and/or MUF resin

Customer benefits

Resin savings up to 15% compared to conventional blow line

Low energy consumption in dryer due to low water load

Can be integrated into existing systems at any time

High board quality due to less resin spots on board surface

Optimized engineering for blow line routing

Technical features

Each nozzle is individually controlled and adjusted by a compact linear motor for a uniform spray pattern

Linear drives and sensors with intelligent IO-Link technology

Resin and steam pressure can be set via a HMI screen and can be adjusted automatically

Each resin nozzle can be flushed individually with fresh water and a high pressure unit during production

Steam atomizing nozzles create small resin droplets

The quantity of nozzles can be extended modularly to increase capacity

Separate pMDI injection closer to the dryer pipe available

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.