- Production Machines

- Forming Machine

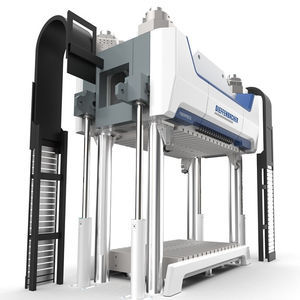

- Hydraulic press

- Dieffenbacher

Hydraulic press bendingjoiningassembly

Add to favorites

Compare this product

Characteristics

- Operation

- hydraulic

- Function

- bending, joining, assembly, embossing

- Structure

- ram, frame

- Force

Max.: 50,000 kN

Min.: 1,000 kN

Description

roducing heat exchanger plates with the highest manufacturing accuracies

For the production of heat exchanger plates, high demands are made on the embossing depth accuracy, the manufacturing accuracy and a high surface symmetry. The Dieffenbacher embossing press can meet these requirements, among other things, thanks to its multi-cylinder solution and solid frame design. Achieve optimum component qualities thanks to the multi-cylinder concept, which ensures parallel deflection of the ram and table. As the pressing forces are freely selectable and the system is equipped with 500bar working pressure, high pressure can be realized even on small surfaces. Thus, you will experience a high degree of flexibility.

Your benefits with embossing presses

Embossing press in frame design to achieve high manufacturing accuracies for assembly and / or joining processes

High frame rigidity and low component deflection

500 bar hydraulic working pressure

Multi-cylinder concept and parallel bending line of table and ram for high and uniform surface pressure to achieve high symmetry tolerances over the embossed plate area

Freely selectable embossing forces

High product quality and economic efficiency

Catalogs

No catalogs are available for this product.

See all of Dieffenbacher‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.