- Industrial machines and equipment

- Surface Treatment Equipment

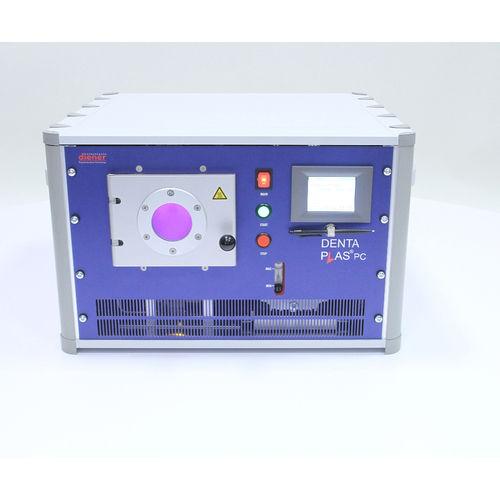

- Plasma surface treatment machine

- Diener electronic GmbH & Co. KG

Plasma surface treatment machine DENTAPLAS PClaboratory

Add to favorites

Compare this product

Characteristics

- Type

- plasma

- Other characteristics

- laboratory

Description

Low pressure plasma systems for dental laboratories

The surface treatment of dental works with low pressure plasma shows the following advantages:

Activation and etching for better adhesion

Plasma allows a form-locking and seamless ocombination of high end plastics (ie. PEEK/PEKK) with other materials.

Activation and etching of surfaces with an ionized mix of oxygen and argon gas in many cases allows abdication of primers.

Oxygen radicals increase the surface energy and the bombardement with argon atoms create a sandblasting-effect, changing the surface topography in the nano-scales. Herewith a retention-base is provided.

By reducing or preventing adhesives, the risk for allergic patients will be minimized. Also, for the dental lab, an interesting cost reducing potential can be realized.

The following materials can be activated, intensive cleaned and etched with Plasma:

PEEK, PEKK, Acetal (POM), PE, PA,or PMMA, Metalls (NM, NNM, Titanium), Zirconia and Ceramics.

Reduction of germs

At a process temperature of approx. 60°C germs and viruses will be destroyed, turned into the gas phase and vacuumed by the integrated pump. Due to the form-locking, seamless properties of plasma, working-parts with complex geometries can be intensive-cleaned.

Environment protection

Plasma is an outstanding environment protective technology. It works with a standard power supply of 110/230 V. Using a high-vacuum of 0.3 mbar, the consumption of process gasses (Oxygen/Argon) is extremely low.

The DENTAPLAS PC offers:

simple and safe handling

optimized processes according to materials

automatic course of action

low process temperatures

integrated vacuum pump

VIDEO

Catalogs

No catalogs are available for this product.

See all of Diener electronic GmbH & Co. KG‘s catalogsOther Diener electronic GmbH & Co. KG products

Low-pressure plasma

Related Searches

- Surface treatment machine

- Vacuum chamber

- Plasma surface treatment machine

- Coating application system

- Automatic surface treatment machine

- Laboratory surface treatment machine

- Surface treatment machine for the printing industry

- PC-controllable surface treatment machine

- 3D part surface treatment machine

- Medical device surface treatment machine

- Portable surface treatment machine

- Vacuum surface treatment machine

- Desmear surface treatment machine

- Fabric surface treatment machine

- Label printing surface treatment machine

- Plate surface treatment machine

- Printed circuit surface treatment machine

- Surface treatment machine for the eyewear sector

- Surface analysis vacuum chamber

- Atmospheric plasma generator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.