- Industrial machines and equipment

- Surface Treatment Equipment

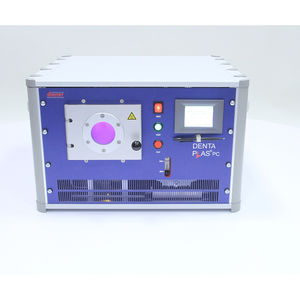

- Plasma surface treatment machine

- Diener electronic GmbH & Co. KG

Plasma surface treatment machine Tetra 320Rautomatic

Add to favorites

Compare this product

Characteristics

- Type

- plasma

- Other characteristics

- automatic

Description

The Tetra 320R production system with its chamber volume of 320 litres and PC control is used in series production (cleaning, etching and activation):

Technical data

Control cabinet: W 870 mm, H (with feet) 1860 mm, D 1400 mm

Chamber: ∅ 640 mm, D 1000 mm

Chamber volume: approx. 320 litres

Gas supply: 2 gas channels via MFCs

Generator: 1 pc. (80 kHz/ 1000 Watt)

Control: PC control (Windows)

Parts holding fixture: according to customer requirements

Plasma processes

Materials cleaning

Plasma technology offers solutions for any type of contamination, for any substrate and any post-treatment. In the process, molecular contamination residues are decomposed as well.

Activation of materials

Good wettability is a prerequisite for the adhesion of binding partners in painting, gluing, printing or bonding.

Etching materials

Plasma technology allows for anisotropic and isotropic etching. Isotropic etching is done by chemical etching and anisotropic etching by physical etching.

Coating of materials

With low-pressure plasmas, components can be tempered with various coats. This is done by supplying gaseous and liquid starting substances into the vacuum chamber.

Catalogs

No catalogs are available for this product.

See all of Diener electronic GmbH & Co. KG‘s catalogsOther Diener electronic GmbH & Co. KG products

Low-pressure plasma

Related Searches

- Surface treatment machine

- Vacuum chamber

- Plasma surface treatment machine

- Coating application system

- Automatic surface treatment machine

- Laboratory surface treatment machine

- Surface treatment machine for the printing industry

- PC-controllable surface treatment machine

- 3D part surface treatment machine

- Medical device surface treatment machine

- Portable surface treatment machine

- Vacuum surface treatment machine

- Desmear surface treatment machine

- Fabric surface treatment machine

- Label printing surface treatment machine

- Plate surface treatment machine

- Printed circuit surface treatment machine

- Surface treatment machine for the eyewear sector

- Surface analysis vacuum chamber

- Atmospheric plasma generator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.