- Industrial machines and equipment

- Surface Treatment Equipment

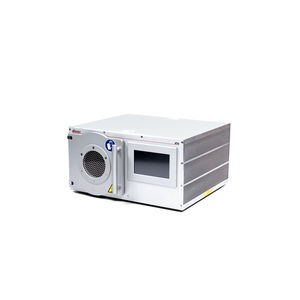

- Plasma surface treatment machine

- Diener electronic GmbH & Co. KG

Plasma surface treatment machine Nanovacuumautomaticlaboratory

Add to favorites

Compare this product

Characteristics

- Type

- plasma

- Other characteristics

- vacuum, automatic, laboratory, for label printing, PC-controllable, for wafers, for printed circuits, for plates, for 3D parts, for the eyewear sector, portable, for medical devices, desmear, for fabrics

Description

Plasma systems from Diener electronic have long since established themselves in a wide range of industrial sectors. With the Nano low-pressure plasma system, you can rely on modern and future-proof cold plasma technology in a vacuum. The chamber volume of 18 up to 24 litres of this plasma system offers enough space to serve laboratory and also series production.

Plasma treatment in low-pressure plasma is a proven technique for controlled ultra-fine cleaning, improvement of adhesion (activation and etching) and coating of thin layers on substrate surfaces. Plasma is generated by applying high-frequency voltage in the vacuum chamber. In the process, the process gas introduced there is ionised.

Fields of application:

VOC-free cleaning of organic residues.

Activation before painting, gluing, potting, ...

Etching of PTFE, photoresist, oxide layers, ...

Super-hydrophobic and -hydrophilic coatings.

Main features:

Benchtop or floor-standing

Vacuum chambers: Stainless steel, aluminium, borosilicate or quartz glass

Chamber volume: 18 - 24 litres

Gas supply: Mass flow controllers (MFCs)

Generator frequencies: 100 kHz (0 - 500 W), 80 kHz (0 - 1000 W), 13.56 MHz (0 - 300 W), 2.45 GHz (0 - 600 W)

Controls: Semi-automatic, rotary switch, basic PC control (Windows CE), full PC control (Windows 10 IoT)

Pressure measurement: Pirani, capacitance manometer

The nano plasma systems are mainly used in the following areas:

Analytics, Archaeology, Automotive, Research and development departments, Semiconductor technology, Small batch production, Plastics technology, Medical technology, Microsystems technology, Sensor technology, Sterilisation, Textile technology.

Catalogs

Other Diener electronic GmbH & Co. KG products

Low pressure plasma systems

Related Searches

- Surface treatment machine

- Vacuum chamber

- Plasma surface treatment machine

- Coating application system

- Automatic surface treatment machine

- Laboratory surface treatment machine

- Surface treatment machine for the printing industry

- PC-controllable surface treatment machine

- 3D part surface treatment machine

- Medical device surface treatment machine

- Portable surface treatment machine

- Vacuum surface treatment machine

- Desmear surface treatment machine

- Fabric surface treatment machine

- Label printing surface treatment machine

- Plate surface treatment machine

- Printed circuit surface treatment machine

- Surface treatment machine for the eyewear sector

- Surface analysis vacuum chamber

- Atmospheric plasma generator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.