- Detection - Measurement

- Flow, Pressure and Level Measurements

- Vacuum leak tester

- DILO Armaturen und Anlagen GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Vacuum leak testing machine for vesselsinjection pumpautomatic

Add to favorites

Compare this product

Characteristics

- Type

- vacuum

- Applications

- injection pump, for vessels

- Other characteristics

- automatic

Description

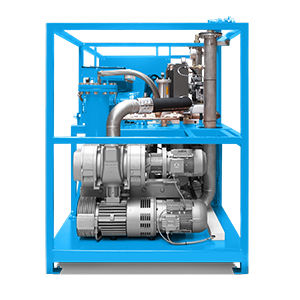

HELIUM LEAK TESTING UNIT

Unit for quick and precise leak testing of vacuum tight series components and helium recovery

Special features

Filling of the test object with helium inside the chamber (integrated gas handling)

Built-in calibration reference leak

Evacuation of the chamber

Test time approx. 5 minutes

Integrated helium recovery

Manual sliding door with pneumatically controlled door lock

Automatic control and colour touch panel with PC connection

Technical data

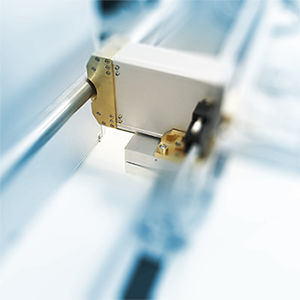

- Leak detection system: mass spectrometer

- Smallest detectable leak rate of the leak measurement system: 1x10-11 mbar l/s

- Chamber size: approx.: 1.3 m³

- Pumping performance: 500 m³/h with final vacuum 1x10-3 mbar

Application examples

Automotive industry

- Common rail injection systems and fuel pumps

- Oil and cooling circuits on cylinder blocks and cylinder heads

- Refrigerant vessels and cooling hoses

- Components of brake systems etc.

Refrigeration and air-conditioning technology

- Heat exchangers, refrigerant hoses, air-conditioning compressors, evaporators, air-conditioning lines, charge air coolers

Plant engineering

- Pumps, fittings, valves

Other fields of application

We recommend DILO helium leak testing units whenever a high tightness level of the components to be tested is required.

Catalogs

No catalogs are available for this product.

See all of DILO Armaturen und Anlagen GmbH‘s catalogsOther DILO Armaturen und Anlagen GmbH products

INDUSTRIAL GAS EQUIPMENT

Related Searches

- Leakage detector

- Leak testing device

- Gas leakage detector

- Automatic leak testing machine

- Portable leakage detector

- Leakage detector with integrated display

- Vacuum leak testing machine

- Industry leakage detector

- Electronic leakage detector

- Vessel leak testing device

- Leak detector with alarm

- Small leak leak detector

- Vacuum leak detector

- Pressure leak detector

- Leak detector with audible signal

- Leak detector with visual alarm

- Sniffing leak detector

- Mobile leak detector

- Wireless leak detector

- Infrared leak detector

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.