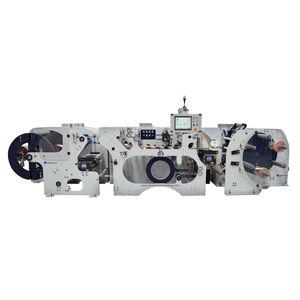

Automatic unwinding-rewinding machine Simplex Seamer

Add to favorites

Compare this product

Characteristics

- Operation

- automatic

- Roll width

50 mm, 254 mm, 600 mm

(1.97 in, 10 in, 23.62 in)

Description

Simplex Seamer

Description

Converting machine for shrinking sleeves. Compact design and easy to operate machine that runs with a wide range of plastic films such as PVC, PET, PETG, OPS and PLA.

Process

- Central unwinder with a 3” inflatable shaft.

- Heat shrinkable sleeve forming system by wheels and paddles.

- Pulling press to isolate tension from unwinder.

- Rewind system with a oscilating movement.

- Central rewind system with a 3” inflatable shaft.

Optional

- Longitudinal perforating system.

- Alignment system.

- Monitoring system for the width of the sleeve with an alarm system.

- UV lamp and adhesive application sensor.

- Inflatable shafts for different diameters.

Technical Specifications

- Unwinding diameter: 800 mm (31.5”).

- Rewinding diameter: 600 mm(24”).

- Maximum width at unwinder: 600 mm (24”).

- Maximum width of formed sleeve: 254 mm (10”).

- Minimum width of formed sleeve: 50 mm (2”).

- Speed: 500 m/min (1,640 ft/min).

Services

- Training.

- Installation.

- Spare parts sales.

- Preventive maintenance.

- Troubleshooting hotline.

VIDEO

Catalogs

SIMPLEX SEAMER

2 Pages

Related Searches

- Inspection machine

- Slitter-rewinder

- Automatic inspection machine

- Automatic slitter-rewinder

- Rewinder-winder

- Industrial inspection machine

- Paper slitter-rewinder

- Plastic film slitter-rewinder

- Roller rewinder-winder

- Paper rewinder-winder

- In-line inspection machine

- Compact slitter-rewinder

- Drive rewinder-winder

- Unwinding-rewinding machine

- Automatic unwinding-rewinding machine

- Fast slitter-rewinder

- Label slitter-rewinder

- Duplex turret slitter-rewinder

- Unwinding machine

- Plastic film inspection machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.