Polyurethanes (PUs) are in a polymer class of their own. Polyether or polyester polyurethanes can be made depending on the choice of co-monomers used to produce them. PUs form a considerable part of the high-performance rubbers and plastics family. They combine the desired benefits of rigid materials with the elasticity of rubbers, bridging the gap between rubbers and plastics in the many industry sectors served by these versatile polymers.

PU rubber used in our polyurethane casting processes can easily be coloured, unlike regular millable rubbers and still exhibit better abrasion properties. Special materials can be added to obtain specific properties such as electrical conductivity. Polyether PUs are more resistant to hydrolysis than their polyester counterparts, giving them better water resistance.

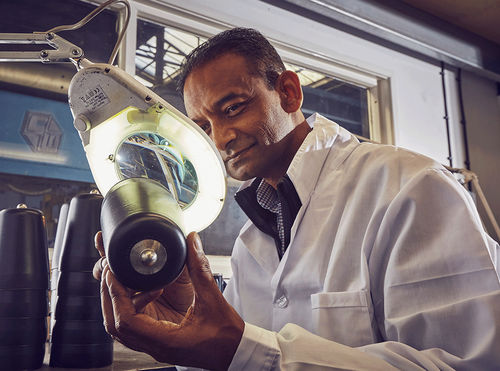

DLR Elastomer Engineering

In general, PU rubber is highly abrasion-resistant, from a hardness of 65 Shore A through to 75 Shore D! They are resistant to oxidation, ozone, sunlight & petroleum-based fuels & oils. PUs are generally considered to be chemical resistant polymers. Strong acids, alkalis and some strong solvents are to be avoided. PUs find continuous use in temperatures of up to 90°C with excursions to as high as 120°C. The resilience of PUs vary dramatically & can be tailored for specific applications.