- Products

- Catalogs

- News & Trends

- Exhibitions

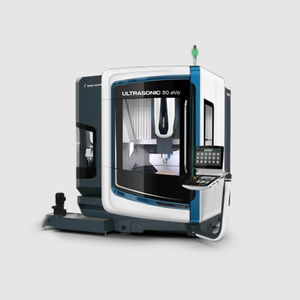

5-axis machining machine 20 linearverticalgantrywith rotary table

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Structure

- gantry, with rotary table

- Spindle mount

- HSK-E32, HSK-E40

- Associated functions

- milling

- Other characteristics

- high-productivity, ultrasonic, compact, high-precision, high-power, with linear motor

- X travel

200 mm

(7.87 in)- Y travel

220 mm

(8.66 in)- Z travel

280 mm

(11.02 in)- Rotational speed

Min.: 6,000 rpm

(37,699 rad.min-1)Max.: 42,000 rpm

(263,894 rad.min-1)- Workpiece max height

200 mm

(8 in)- Table load capacity

100 kg

(220 lb)

Description

Process forces reduced by up to 50% through ULTRASONIC enable, depending on requirements: higher feed rates, improved surface quality up to Ra 2g acceleration and absolute longterm stability

Linear drives in X / Y / Z with > 2 g acceleration

50% stronger drives in the A-axis

Stable, FEM-optimised, vibration-damping mineral composite column

Integrated linear magazine PH 10 | 100 with max. 99 pallet places (max. 10 kg handling weight)

Compact footprint with only 6 m²

Flexible integration of all available clamping systems

Customer specific expansion modules available on request

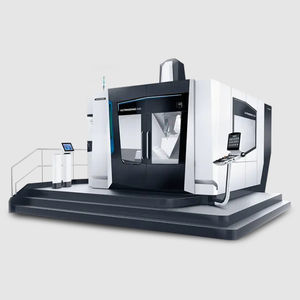

Standard automation and customised solutions in the VERTICO design

Automation is a key element of digital production. Every DMG MORI machine can be upgraded with standard automation or with a customised automation solution for flexible manufacturing systems:

Related Searches

- DMG MORI machining center

- DMG MORI vertical machining center

- DMG MORI lathe

- DMG MORI CNC lathe

- DMG MORI 3-axis machining center

- DMG MORI 2-axis lathe

- DMG MORI precision machining center

- DMG MORI CNC milling machine

- DMG MORI 5-axis machining center

- DMG MORI vertical CNC milling machine

- DMG MORI high-precision machining center

- DMG MORI 3-axis CNC milling machine

- DMG MORI rigid machining center

- DMG MORI high-performance machining center

- DMG MORI high-precision lathe

- Drilling machine

- DMG MORI gantry machining center

- DMG MORI high-rigidity machining center

- 12 tools turning center

- Milling CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.