- Products

- Catalogs

- News & Trends

- Exhibitions

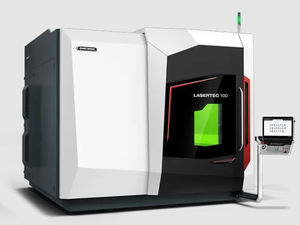

Automatic laser ablation system LASERTEC 50 Shape Femto

Add to favorites

Compare this product

Characteristics

- Options

- automatic

Description

5-axis laser precision machine for complex prototypes as well as special processing

made of carbide, powder-metal steels, ceramics and other advanced materials.

Linear drives with acceleration > 1 g

Highly dynamic torque motors in both rotary axes (B- and C-axis)

Compact machine design with only 4 m² footprint

Best machine features for high-end machining

Tunable laser source with variable pulse length and burst modes

High positioning accuracy of ≤ 8 μm

CCD camera and 3D measuring probe for fast setup

3D laser ablation for the production of miniature molds, extrusion dies, inscriptions and engravings

Contact-free machining without need of electrodes and without tool wear

Highest repeatability and reproducability

Machining of standard materials up to Advanced materials like glass, ceramics and tungsten carbide

Surface qualities up to Ra < 0,1 µm in carbide tools

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.