- Products

- Catalogs

- News & Trends

- Exhibitions

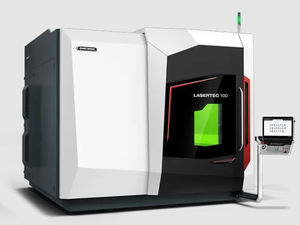

Laser drilling machine LASERTEC 50 PowerDrillCNC5-axisfor profiles

Add to favorites

Compare this product

Characteristics

- Type

- CNC

- Number of axes

- 5-axis

- Applications

- for profiles

- Other characteristics

- high precision, laser

Description

Technology leader in 5-axis precision laser drilling of cooling holes for aerospace and energy turbines (IGT)

Contact-free machining without need of electrodes and without tool wear

Highest repeatability and reproducability

Different laser sources for various applications

Shaped hole machining up to 10x faster than wire EDM and highest design liberty for the geometries

Laser precision machine for all demanding 5-axis drilling applications up to Ø 300 mm x 350 mm part size

Linear drives in X / Y with acceleration > 1 g as well as highly dynamic torque motors in both rotary axes (B- and C-axis)

Clear structured working area with best accessability to the workpiece

Compact machine design with only 4 m² footprint

Best machine features for High-End-Machining

High positioning accuracy of ≤ 8 μm

CCD camera and 3D measuring probe for fast setup

High precision QCW-fibre laser (up to 23 kW)

PowerDrill and PowerShape machine versions available

Laser drilling using PowerDrill and creating shaped holes with conical exit fans using PowerShape machine version.

Complete series with Siemens 840D solutionline and dedicated software features for laser machining (LASERSOFT PowerDrill / PowerShape)

Holistic process chain with drilling and fan shaping by using both machine versions, LASERTEC PowerDrill and PowerShape and gaining the benetifs of data transfer and repeatability.

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.