- Products

- Catalogs

- News & Trends

- Exhibitions

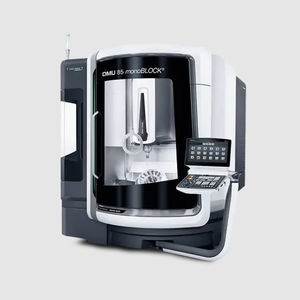

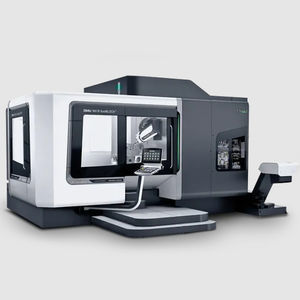

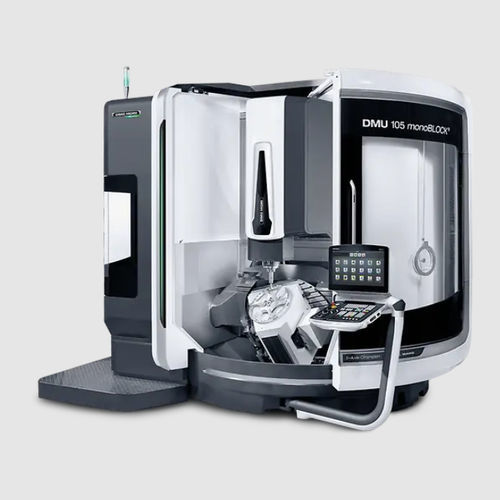

5-axis CNC milling center DMU 105 (FD) monoBLOCKverticalfor the automobile industryfor molds

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Applications

- for the automobile industry, for molds

- Other characteristics

- precision

- X travel

1,135 mm

(44.69 in)- Y travel

1,050 mm

(41.34 in)- Z travel

750 mm

(29.53 in)- Rotational speed

30,000 rpm

(188,496 rad.min-1)- Workpiece max height

690 mm

(27 in)- Table load capacity

2,000 kg

(4,409 lb)- Positioning accuracy

5 µm

Description

Ergonomic

Large door opening of 1,650 and unique access to the working area, most compact machine with a footprint of just 18 m²

Quick and easy to set up thanks to it´s three-point support

Comprehensive cooling measures, high-performance coolant unit and multi-sensor compensation as standard

Stiff construction with high static masses and balanced moving parts

Versatile

Machineintegrated tool magazines with up to 180 pockets

Stiff monoBLOCK concept

monoBLOCK – Maximum stability from one casting

One-piece column with large, stable slideways, 55 mm roller guideways in all axes

Maximum stability thanks to large ball screws in all axes ø 50 / 63 / 50

FEM optimisation of all components

Clamping of the swivelling rotary table

VIDEO

Related Searches

- DMG MORI machining center

- DMG MORI vertical machining center

- DMG MORI lathe

- DMG MORI CNC lathe

- DMG MORI 3-axis machining center

- DMG MORI 2-axis lathe

- DMG MORI precision machining center

- DMG MORI CNC milling machine

- DMG MORI 5-axis machining center

- DMG MORI vertical CNC milling machine

- DMG MORI high-precision machining center

- DMG MORI 3-axis CNC milling machine

- DMG MORI rigid machining center

- DMG MORI high-performance machining center

- DMG MORI high-precision lathe

- DMG MORI gantry machining center

- DMG MORI high-rigidity machining center

- Drilling machine

- Milling CNC machining center

- 12 tools turning center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.