- Products

- Catalogs

- News & Trends

- Exhibitions

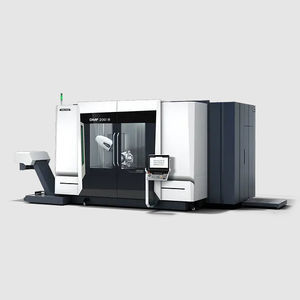

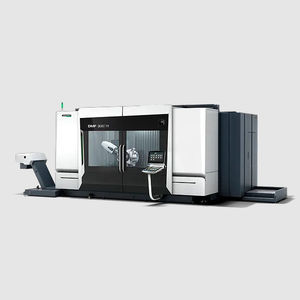

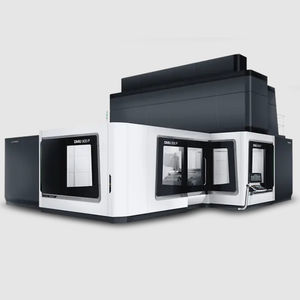

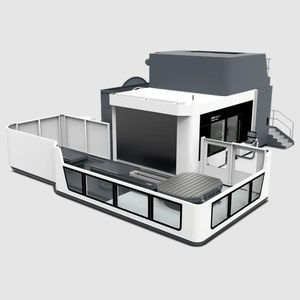

CNC milling-turning center DMF 300|8 (FD)vertical4-axis5-axis

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Type

- vertical

- Number of axes

- 5-axis, 4-axis

- Structure

- spindle

- Other characteristics

- high-productivity, modular

- Diameter

1,050 mm

(41.34 in)- X travel

3,000 mm

(118.11 in)- Y travel

800 mm

(31.5 in)- Z travel

850 mm

(33.46 in)

Description

Maximum Flexibility

4-axes or 5-axes machining with B-axis and integrated NC table

Mill-Turn Technology for machining of highly complex geometrics on one machine (optional)

New basic construction with constant overhang in the whole working area

3 linear guide ways in X-axis and single piece machine bed made of cast iron

Spindles from 15,000 to 20,000 rpm and up to 200 Nm

High accuracy and best surface quality of the machined workpieces

Very high thermal longterm accuracy based on comprehensive cooling measures

Direct drives in Y- and Z-axis

Dynamic package with linear drive in X-axis (optional)

Maximum productivity for your shopfloor

Unique tool change ouside of the working area

Tool magazine with up to 120 pockets and a tool length of up to 400 m

Variety of machine tables - perfect for all requirements

Avoidance of idle times based on the optional partition wall (optional)

Increase of productivity based on DMG MORI Technology Cycles, e.g. angularTOOL

VIDEO

Related Searches

- DMG MORI machining center

- DMG MORI vertical machining center

- DMG MORI lathe

- DMG MORI CNC lathe

- DMG MORI 3-axis machining center

- DMG MORI 2-axis lathe

- DMG MORI precision machining center

- DMG MORI CNC milling machine

- DMG MORI 5-axis machining center

- DMG MORI vertical CNC milling machine

- DMG MORI high-precision machining center

- DMG MORI 3-axis CNC milling machine

- DMG MORI rigid machining center

- DMG MORI high-performance machining center

- DMG MORI high-precision lathe

- Drilling machine

- DMG MORI gantry machining center

- DMG MORI high-rigidity machining center

- 12 tools turning center

- Milling CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.