- Products

- Catalogs

- News & Trends

- Exhibitions

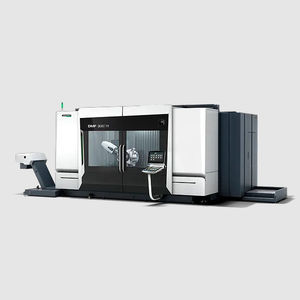

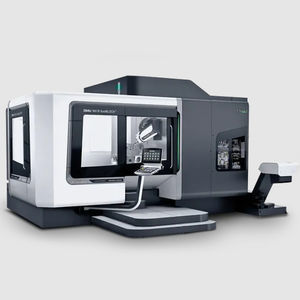

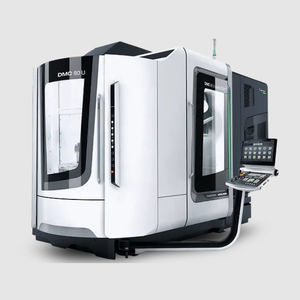

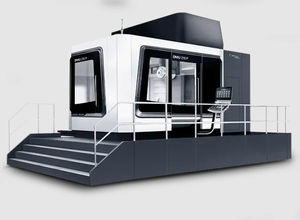

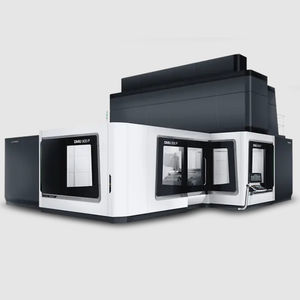

CNC milling-turning center DMU 80 P (FD) duoBLOCKuniversal5-axisspindle

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Type

- universal

- Number of axes

- 5-axis

- Structure

- spindle

- Other characteristics

- high-performance, high-power, cutting, precision, direct-drive

- Diameter

950 mm

(37.4 in)- X travel

800 mm

(31.5 in)- Y travel

1,050 mm

(41.34 in)- Z travel

850 mm

(33.46 in)

Description

Complete machining

Milling and turning in one setup with the DirectDrive table and rotational speeds up to 800 rpm

Best surface quality with technology integration grinding

Maximum accuracy through completely water-cooled feed drive

SGS: Spindle Growth Sensor for Compensation of spindle increase

Significantly improved temperature response

Up to 50 % higher cutting power with the roughing package

Also available in mill- /turn - version

powerMASTER motorspindle with 1,000 Nm and 77 kW

5X torqueMASTER with 1,300 Nm and 37 kW

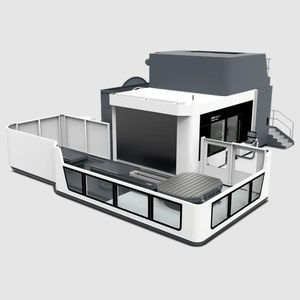

Efficiency

Low space requirements, extremely compact wheel magazine with short tool replenishment time

Optimal ease of maintenance and ideal ergonomics thanks to unrestricted accessibility

High machine availability with 96 %

duoBLOCK series. Always precise!

Maximum stiffness for the highest machining performance!

Large YRT-Bearing diameter in the B- and C-Axis.

Wide linear guides with 55 mm for a high table load of 1,800 kg

Internnally cooled ball screws ø 50 / 50 / 50 mm as Standard

FEM optimisation of all components

VIDEO

Related Searches

- DMG MORI machining center

- DMG MORI vertical machining center

- DMG MORI lathe

- DMG MORI CNC lathe

- DMG MORI 3-axis machining center

- DMG MORI 2-axis lathe

- DMG MORI precision machining center

- DMG MORI CNC milling machine

- DMG MORI 5-axis machining center

- DMG MORI vertical CNC milling machine

- DMG MORI high-precision machining center

- DMG MORI 3-axis CNC milling machine

- DMG MORI rigid machining center

- DMG MORI high-performance machining center

- DMG MORI high-precision lathe

- Drilling machine

- DMG MORI gantry machining center

- DMG MORI high-rigidity machining center

- Milling CNC machining center

- 12 tools turning center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.