- Products

- Catalogs

- News & Trends

- Exhibitions

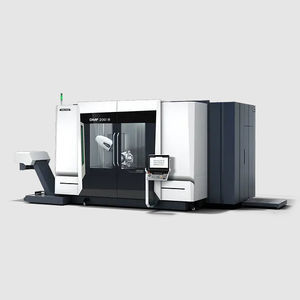

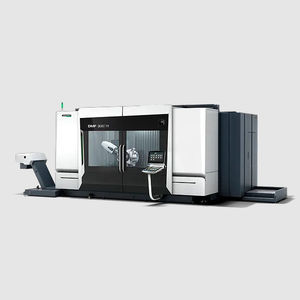

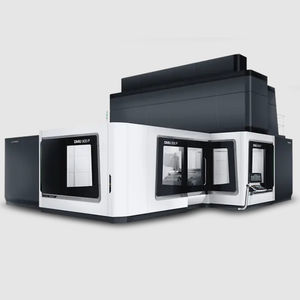

5-axis CNC milling center DMU 340 verticalgantryfor large workpieces

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Structure

- gantry

- Applications

- for large workpieces

- Other characteristics

- precision, high-rigidity

- X travel

6,000 mm

(236.22 in)- Y travel

2,800 mm

(110.24 in)- Z travel

1,500 mm

(59.06 in)- Workpiece max height

1,540 mm

(61 in)- Work feed X-axis

40,000 mm/min

(26 in/s)- Work feed Y-axis

40,000 mm/min

(26 in/s)- Work feed Z-axis

40,000 mm/min

(26 in/s)- Table load capacity

30,000 kg

(66,139 lb)

Description

Maximum accuracy through water-cooled feed drives

Band filter unit with 2,500 l as standard

Highest long-term accuracy due to cooled linear guideways and active spindle growth control.

Performance

High feed power up to 50 kN

Biggest spindle range in the market: powerMASTER motor spindle with up to 1,000 Nm and torqueMASTER gear spindle with 1,800 Nm

Efficiency

Lower energy consumption through intelligent needs-based power units.

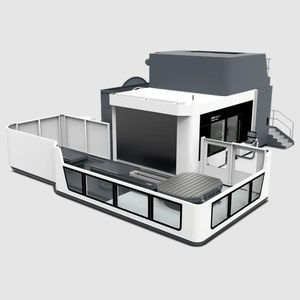

Gantry design with vertically moving cross beam with hydraulic weight compensation.

Fast innovative wheel type magazine with up to 243 tools with minimized footprint.

Thermosymetrical construction

3-point support with an inherently stiff machine bed, no foundation required

High temperature stability standard with positioning accuracy down to 15 µm

Position accuracy down to 12 µm with accuracy pack option

Short and continuous throat depth of milling head (no ram design)

VIDEO

Related Searches

- DMG MORI machining center

- DMG MORI vertical machining center

- DMG MORI lathe

- DMG MORI CNC lathe

- DMG MORI 3-axis machining center

- DMG MORI 2-axis lathe

- DMG MORI precision machining center

- DMG MORI CNC milling machine

- DMG MORI 5-axis machining center

- DMG MORI vertical CNC milling machine

- DMG MORI high-precision machining center

- DMG MORI 3-axis CNC milling machine

- DMG MORI rigid machining center

- DMG MORI high-performance machining center

- DMG MORI high-precision lathe

- Drilling machine

- DMG MORI gantry machining center

- DMG MORI high-rigidity machining center

- 12 tools turning center

- Milling CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.