- Products

- Catalogs

- News & Trends

- Exhibitions

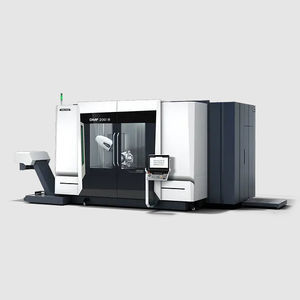

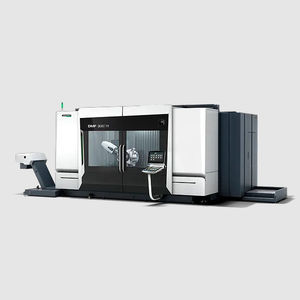

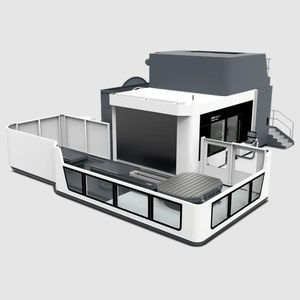

5-axis CNC milling center DMU 600 P (FD)universaldouble tablefor large workpieces

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- universal

- Structure

- double table

- Applications

- for large workpieces

- Other characteristics

- precision, high-rigidity

- X travel

18,750 mm

(738.19 in)- Y travel

4,800 mm

(188.98 in)- Z travel

3,500 mm

(137.8 in)- Workpiece max height

2,500 mm

(98 in)- Work feed X-axis

60,000 mm/min

(39 in/s)- Work feed Y-axis

60,000 mm/min

(39 in/s)- Work feed Z-axis

60,000 mm/min

(39 in/s)- Table load capacity

80,000 kg

(176,370 lb)

Description

Precision

Maximum stiffness and high temperature stability

All relevant heat sources are liquid-cooled

Optimised machine concept based on FEM and modal analysis in portal design

Performance

Also available in mill- /turn - version

Changeable heads with B-axis kinematics for gear spindle and C-/A- and C-/B-axis kinematics for motor spindle

Efficiency

Energy-efficient coolant units

Optional conncection to on-site / customer-site cooling circuit

Version with double table and multi table available.

Maximum rigidity

Shortest installation times through modular design of individual assembly groups

Gear rod drive in the X-/Y-axis

Ball screw drive in Z-/ W-axis for highest dynamics

Machine bed, column and crossbeam from EN-GJS-600-3 with excellent damping characteristics

Large dimensions with high temperature stability

Related Searches

- DMG MORI machining center

- DMG MORI vertical machining center

- DMG MORI lathe

- DMG MORI CNC lathe

- DMG MORI 3-axis machining center

- DMG MORI 2-axis lathe

- DMG MORI precision machining center

- DMG MORI CNC milling machine

- DMG MORI 5-axis machining center

- DMG MORI vertical CNC milling machine

- DMG MORI high-precision machining center

- DMG MORI 3-axis CNC milling machine

- DMG MORI rigid machining center

- DMG MORI high-performance machining center

- DMG MORI high-precision lathe

- Drilling machine

- DMG MORI gantry machining center

- DMG MORI high-rigidity machining center

- 12 tools turning center

- Milling CNC machining center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.