Process forces reduced by up to 50% through ULTRASONIC enable, depending on requirements: higher feed rates, improved surface quality up to Ra <0.1 µm, longer tool life

Specific coolant treatment systems with centrifuges, optimized for the ULTRASONIC processing of Advanced Materials

Constant amplitude in the process to ensure reproducibility

Automatic detection of the working frequency, significantly improved hardware for signal acquisition

Frequency tracking and simultaneous power control in real time for optimal process stability

Flexibility through spindle versions

Ready for new technologies like Ultrasonic, Laser or machining of carbon material

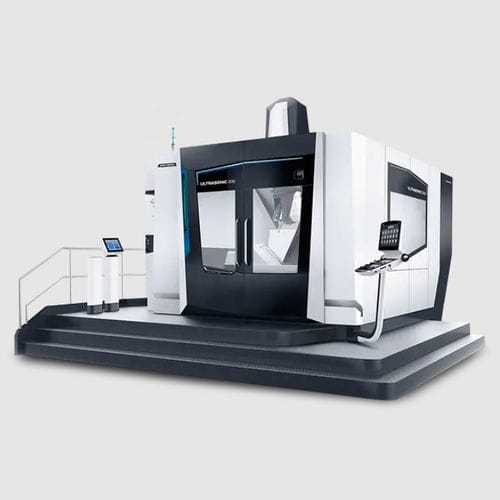

Working area concept

T-slots across the table for easy chip removal

Chip conveyors on both sides of the table

Low Gantry Design

Best visibility into the working area through missing side walls

Maximum utilisation of the working area

45° head with 90° swivel range and +/- 300° rotating range

90° head with +/- 120° swivel range and +/- 300° rotating range