- Products

- Catalogs

- News & Trends

- Exhibitions

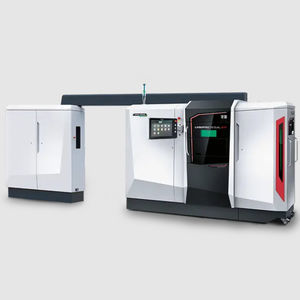

5-axis CNC milling and additive manufacturing machine LASERTEC 125 DED hybridverticallaserhigh-performance

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- vertical

- Other characteristics

- laser, high-performance, high-power

- X travel

1,335 mm

(52.56 in)- Y travel

1,250 mm

(49.21 in)- Z travel

900 mm

(35.43 in)- Rotational speed

20,000 rpm

(125,664 rad.min-1)- Power

3,000 W

(4.08 hp)- Table load capacity

2,000 kg

(4,409 lb)

Description

Proven monoBLOCK design for the best machine performance

Large door opening of 1,900 mm and unique access to the work area with minimal space requirements

Comprehensive cooling measures, powerful cooling unit and multi-sensor compensation as standard

High flexibility of manufacturing processes by combining welding and milling on one machine for additive manufacture and repair

The laser deposition head is handled by a fully automatic shuttle without manual intervention

AM Assistant for the best process reliability and comprehensive traceability

Integrated thermal imaging camera for observation of the whole working area, adapive process control and constant monitoring of the working distance

Powder feed rate sensor as well as automatic powder calibration.

AM Evaluator for visualisation of the relevant process data (e. g. meltpool size, powder mass flow) as a digital 3D-model as well as in the chronological sequence

Siemens NX: Complete Hybrid CAD / CAM – Module for additive and subtractive programming

One software package for the complete process chain (design, additive process, substractive machining, finishing)

Exclusive LASERTEC build-up strategies - fully integrated in the CAD / CAM software incl. 3D-simulation of machine movements for collision prevention

Change between additive and machining programming strategies all within one programming environment.

Using Multi-Materials and Gradient Materials for Improved Part Performance

Selectively adding materials with more than 60 Rockwell to avoid heat treatment processes

Improving cooling performance by using bronze material in the mould core

VIDEO

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.