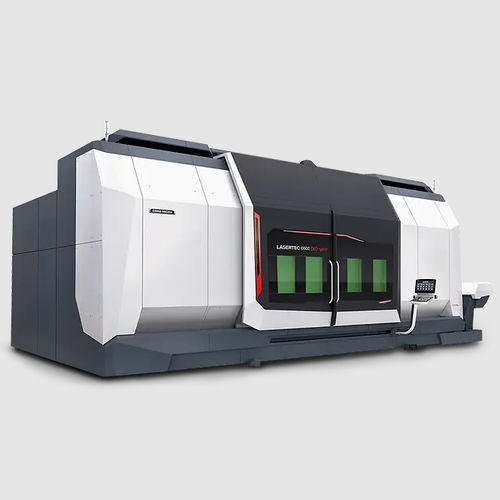

Large Build Area

Largest workpiece size: Φ1,010 mm × 3,702 mm

Suited for large workpieces including rocket engine parts for the aerospace industry, oil-well pipes for the energy industry and shafts for transport aircrafts

Hybrid of metal additive manufacturing technology and subtractive machining

Efficient additive manufacturing and subtractive manufacturing on one machine with the linear axes (X-, Y-, and Z-axis), B-axis (turn-mill spindle), C-axis (Left spindle and Right spindle)

Synchronized operation of Left spindle and Right spindle that transfers workpieces between the two spindles to achieve streamlined additive manufacturing processes

Turn-Mill spindle equipped with the AM head and AM nozzle to carry out metal powder injection and laser irradiation simultaneously

Extensive maintenance functions

Movable and high-performance dust collection duct to prevent dust powder from scattering

Zero Sludge Coolant Tank that effectively collects fine sludge inside the coolant tank as standard

Laser sensor installed on the machine cover and window to detect laser before it penetrates the cover and stop it